The Dogson-2 Telescope

Fast Find >> Mirror,

Pitch,

Pitch

lap, Polishing cradle, Polishing

strokes, Stroke speed, MOT,

Diagonal,

Leave it sphere?, TheAlt-Alt

option, Polishing out pits, Testing,

The

laser test,

The Jerry test,

Ronchi test,

More

Ronchi,

The star test, Rez test,

Aluminizing,Collimation,

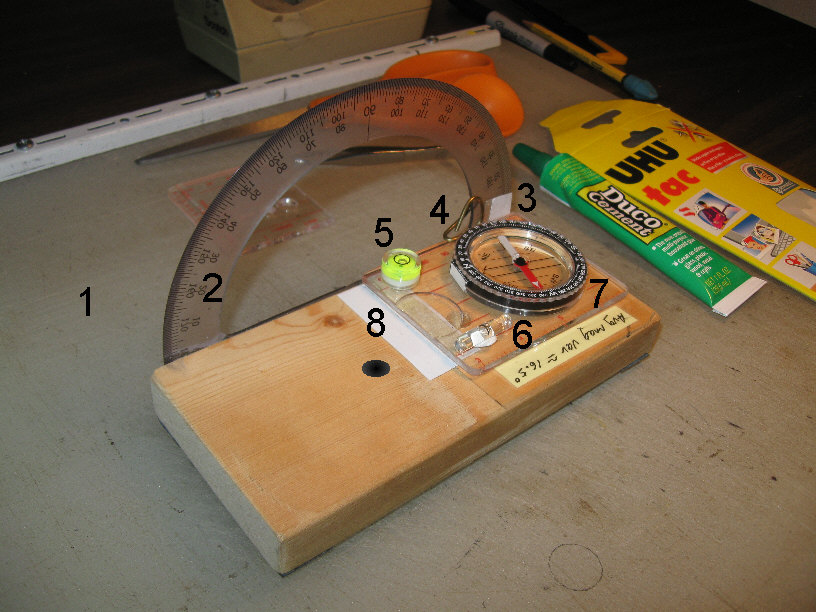

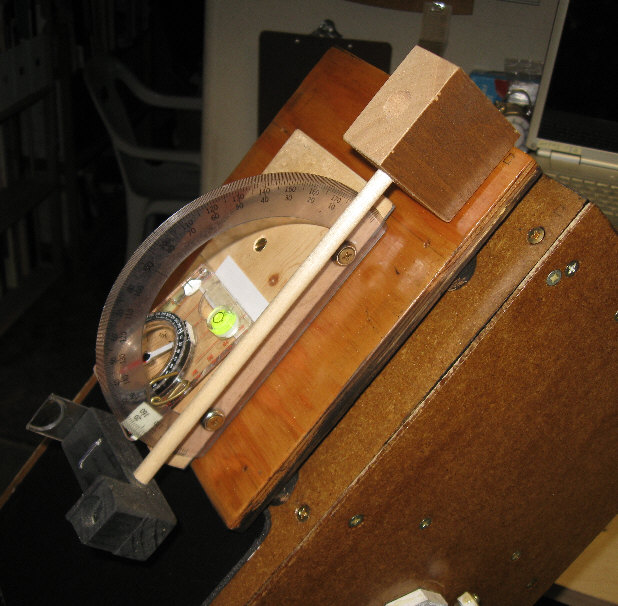

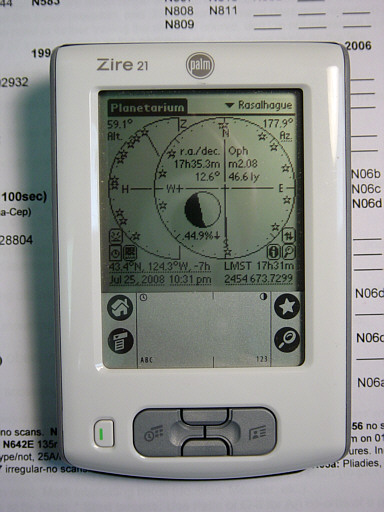

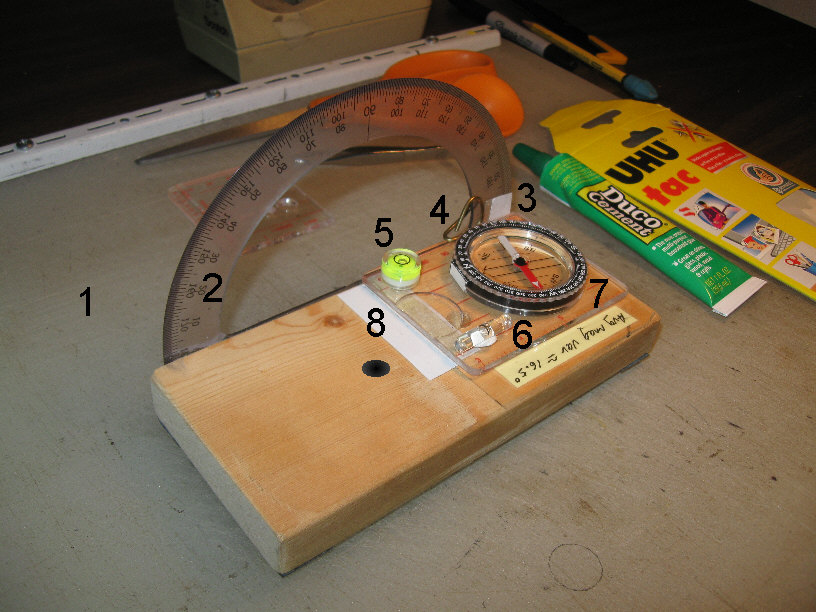

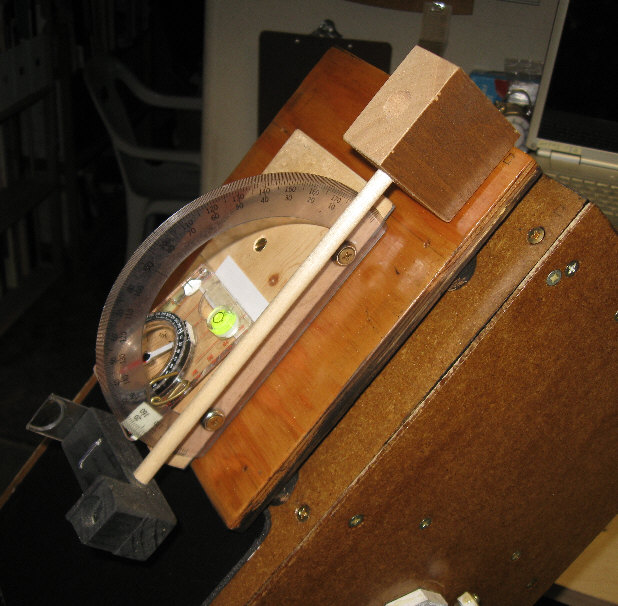

Sky

compass,

Storage,

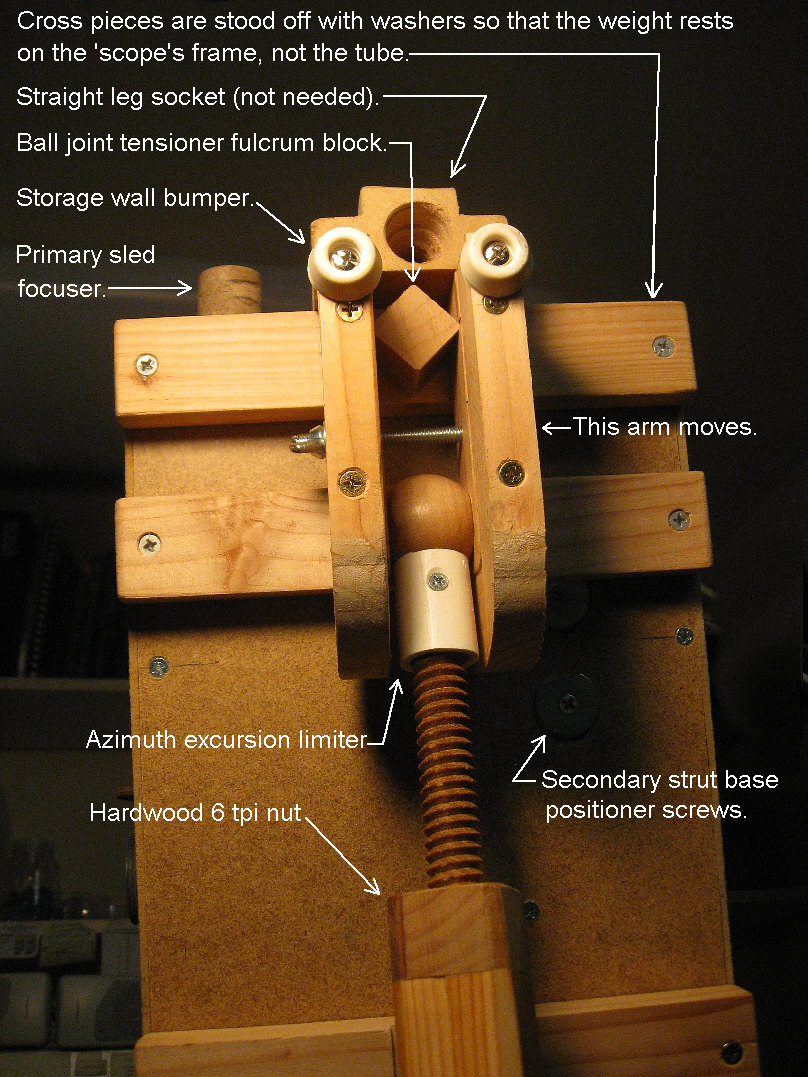

Foreleg, Focusers,

Glow

finder, Cleaning,

Modernity,

Null

test, Reflectivity, Coatings,

A

finder 'scope,

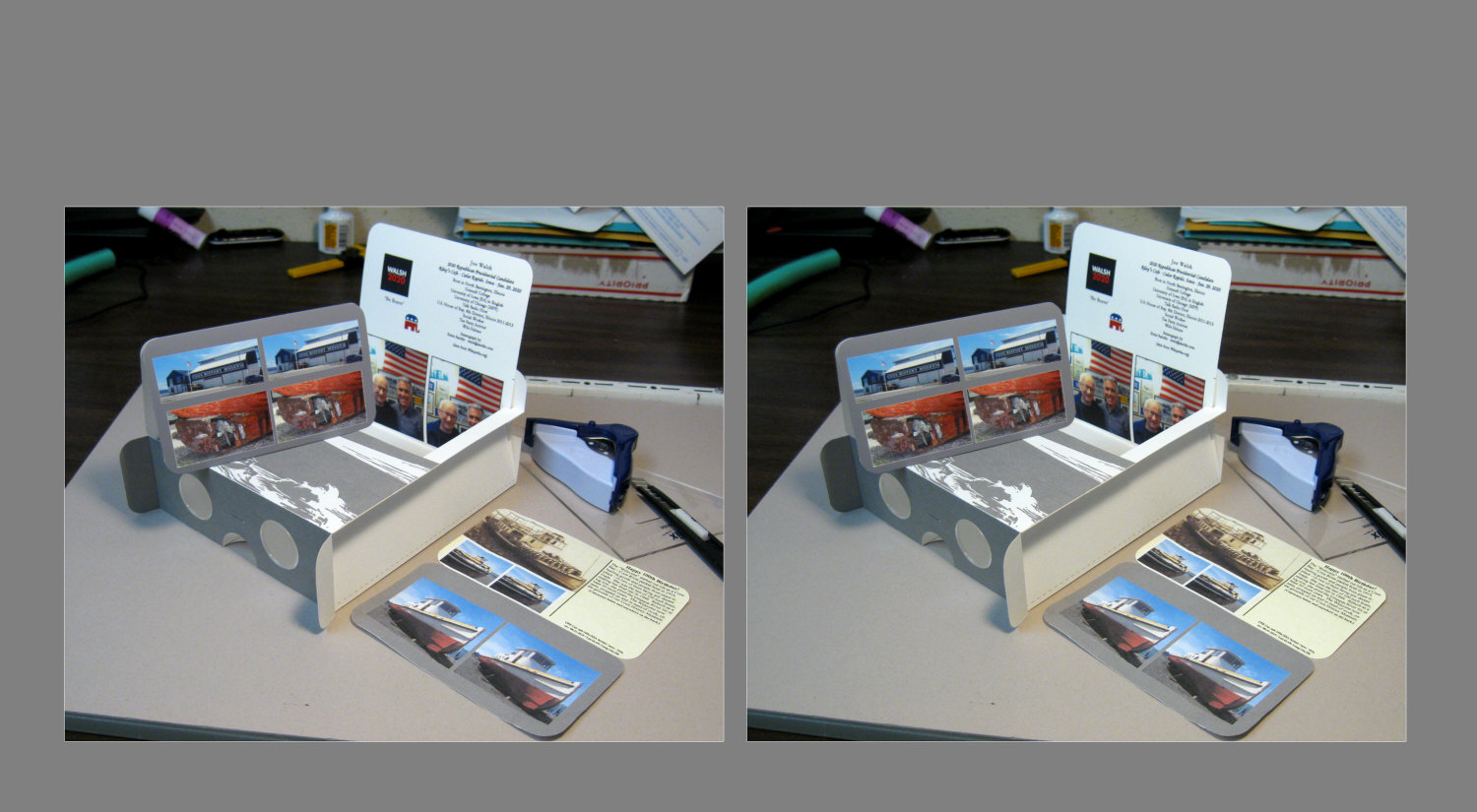

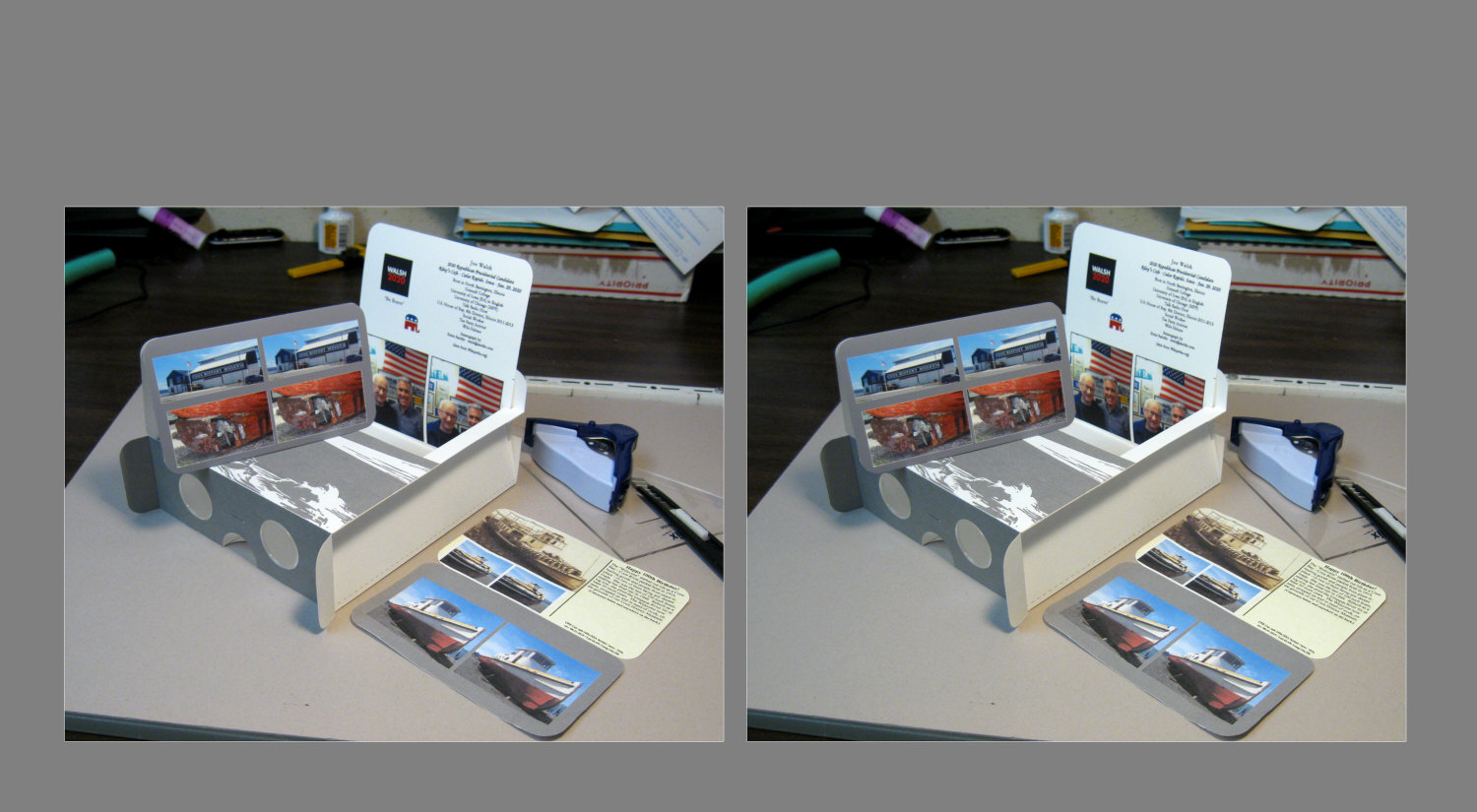

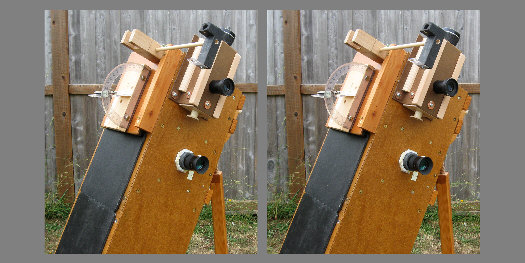

a stereo pair

You're at: https://57296.neocities.org/dog-2.html

(Last worked on: October 25th,

2022.)

>This page attempts to confine

itself to just the making, accessorizing and the using --of a Dogson telescope<

* For a more complete and traditional background

on ATMing, try the following link: https://stellafane.org/tm/index.html

For an excellent overview of amateur astronomy, see:

https://www.handprint.com/ASTRO/atm.html

Hold "Ctrl" and tap "+" for larger text.

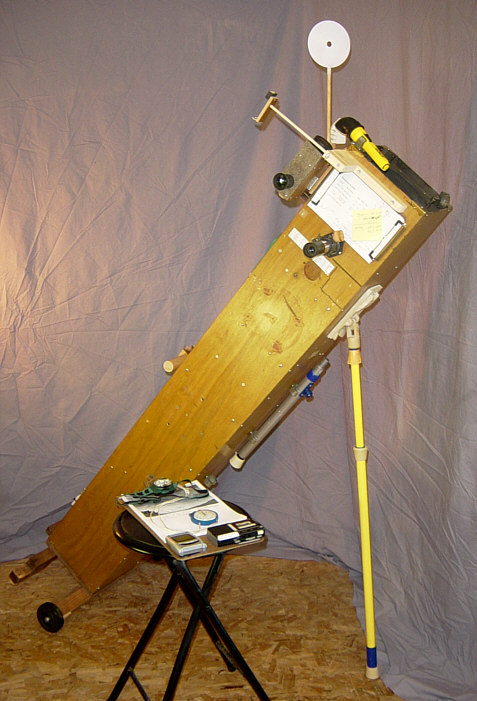

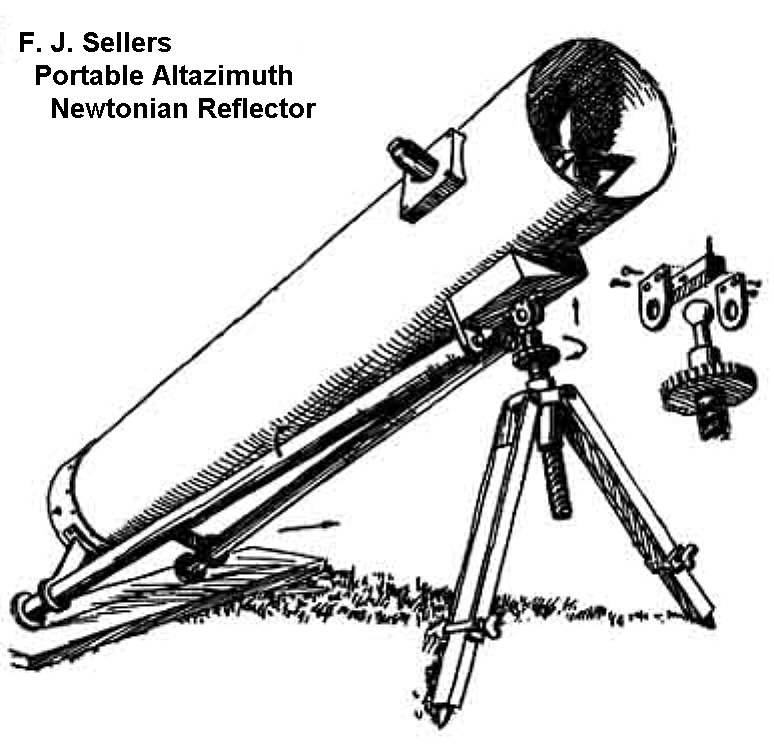

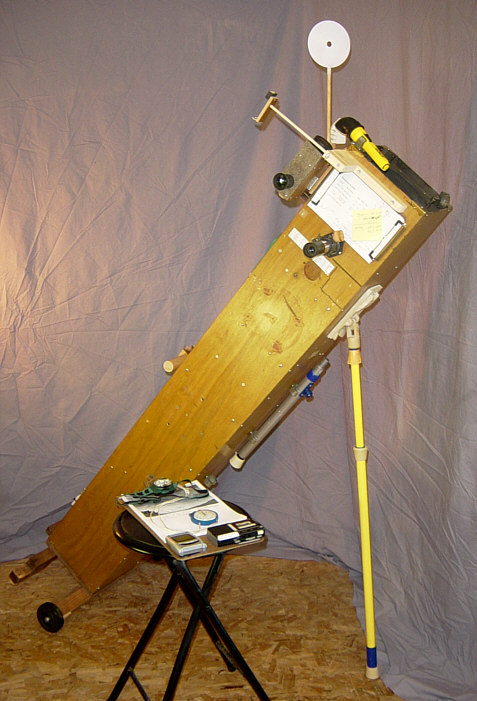

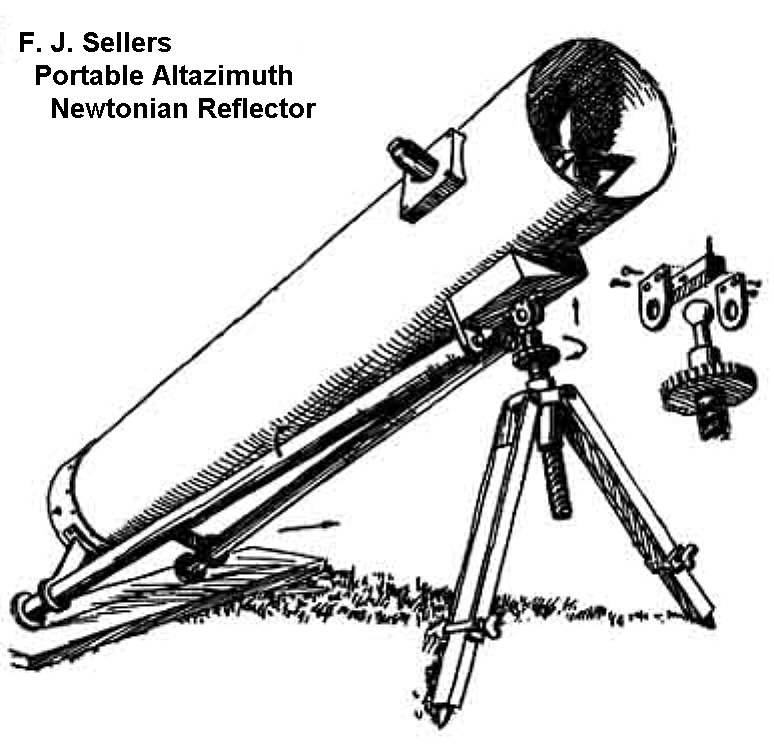

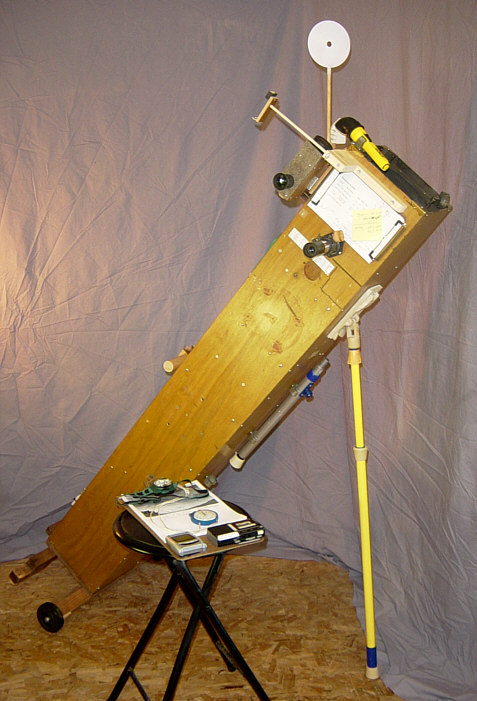

* To design the Dogson I started with the standing and

the stool sitting eyeball height of young people and myself, then built

an affordable, do-able telescope around that dimension: one that's (hopefully)

inherently stable, vibration free, easy to transport, simple to set up

and collimate, intuitive to steer around and adequate for the less than

ideal skies most of us live beneath. I ended up with traditional (6" x

f/8 to f/9) optics.

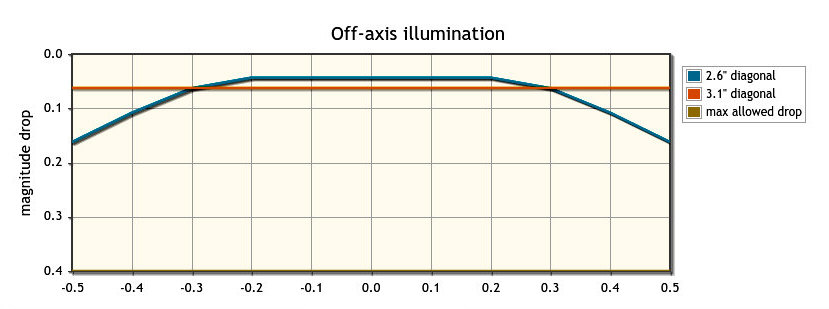

It turned out to be a 5.75" by f/8.74 (as

masked) with 75% illumination (secondary limited) to the edge of a

.85 degree (51 minute) field of view, and is quite usable for a (one magnitude

dimmer at the edge) 1.25 degree field with an affordable (say: $40) 32mm

eyepiece.

For wider angle observing, I've got a pair of Russian

20/80 binoculars (2.75 degrees) and a pair of excellent

10x50 Brunton binoculars (6+ degrees, purchased at a close-out price).

A wee bit of disjointed

ATMing & observing philosophy:

(more of this sort of

talk on page-1)

* An eye full of stars is an eye full of stars, whether

seen through a honking "richest field" telescope or a blackened toilet

paper tube. The point is to pay attention, know or learn what you're looking

at, to log what you can of it ("progress made good"), and to possibly make

a discovery --but without turning an enjoyable avocation into a miserable

pain-in-the-ass (I'm still working on that part :-) and letting astronomy

overload your life. Since observing is mostly done in the dark, damp, cold

hours of the night, it can easily get out of proportion and become an experience

that you tend to postpone. Have goals, but reasonable ones. As for traveling

to dark sites, will that be sustainable in the long term, for the doing

of personal astronomy? "Happiness is in your own back yard."

* Where I live, it's particularly chilly and damp at

night, often with but brief clear sky opportunities. Lately I've been wondering

if I should take another stab at celestial photography --and study my astrographs

instead of standing out there in the cold (then use my good Dogson for

a closer look at a thing or two in particular). (In that regard, I finally

broke down and tried doing some image stacking, which gave me significantly

more magnitude reach with just a few frames.)

* But there will always be stuff that's beyond the

reach of your eye and your instruments. Instead of straining at your limits,

simply pay good and accurate attention to what's at hand. Useful and even

innovative work (VSOing, meteor counts, binaries, comets, Lunar events)

can be done with a log book/device, method, clock, and minimal observing

equipment.

* As to telescopes, Nils Olof Carlin's suggested collimation

tolerances imply that the making of a successful telescope can be a fairly

casually executed project --or it can become a bit of a struggle to maintain

your instrument within tight error limits. (If your telescope is well made

(ie: rigid) then even a short focus 'scope might only need a little tweak

at the start of each session, after which the alignment will hold as you

swing it about.)

Carlin suggests that your scope's optical tube assembly

("OTA") and the alignment of its optics should be within the following

tolerances --through to the lateral drift of its prime focus (regardless

of the objective's diameter):

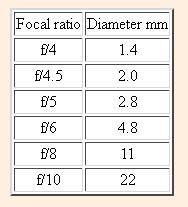

f/4 = +/-0.7mm; f/4.5 = +/-1mm; f/5 = +/-1.4mm;

f/6 = +/-2.4mm; f/8 = +/-5.5mm; f/10 = +/-11mm

Comparatively, then: the build quality and maintenance

of an f/8 or longer Newtonian scope appears to be a "walk in the park"

--if its aperture doesn't exceed about 8 inches or 200mm. (Any larger/longer

and you'll be stumbling around in the dark with a slippery wet step-stool

or ladder.)

* See here for

more about choosing an ATM project.

** Another consideration in the decision to make,

buy or repurpose optics for a telescope --is that the grind and polish

ATM will be working with an assortment of unusual substances. Aside from

silvering chemistry (which few of us any longer engage in), there's glass

dust, fine grinding and polishing compounds. You want to avoid scattering,

inhaling and ingesting these items, or letting kids play in or have access

to the area. You also want to avoid flushing coarser grinding compounds

and sludge/slurry down household drains --where it might clog up.

The polishing compound sold as "cerium oxide" is special

in that it's made up of variable components, one of which might be radioactive

(as is the batch I'm using). Here's the list from an old MSDS sheet:

"Rare Earth Oxide": 30% - 65% (presumably: that's

the nominal cerium oxide --Craig)

Calcium Oxide:

10% - 15%

Strontium Oxide:

1% - 6%

Alumina Silicate:

1% - 40%

Fluorides:

4% - 10%

Silica:

2%

* The stuff I bought and used was tan colored and it

really made my Geiger counter click. Clearly, this is a poorly defined

and controlled substance. Though not listed, the radioactive component

is sometimes said to be thorium. My sample was a heavy beta emitter. [I

don't know if there's any alpha.]

But there's good news on that. "Got Grit" sells "white"

cerium oxide. Jerry Oltion kindly sent me a sample and I got no clicks

above normal background here.

** As you'll see by my polishing and figuring notes,

I found my 6 inch mirror damnably difficult to make --at least this first

time through the course. Such problems as I experienced are usually written

off to the errors of newbie ATMers, but an experienced and very active

voice at the Eugene, Oregon club advises beginners to start instead with

a shorter focus 8 or 10 inch mirror. He recounts that, despite his many

[exemplary, I'll add] telescope project successes since, his only failed

and abandoned mirror was a traditional 6 inch. More-over, he's not seen

but one really good 6" mirror. (I made a good spherical 8 inch x f/10 mirror

60 years ago with no special problems.)

So at this point, I've made a "good" 6 inch mirror

(by my humble standards), but only after 76 hours of polishing(!) --work

which should have taken me about 6 hours. Only the making of my second

6 inch mirror will demonstrate if I've finally got the small mirror process

bolted down.

Never-the-less, I'm presenting what appear to be the

methods, tools and materials which worked.

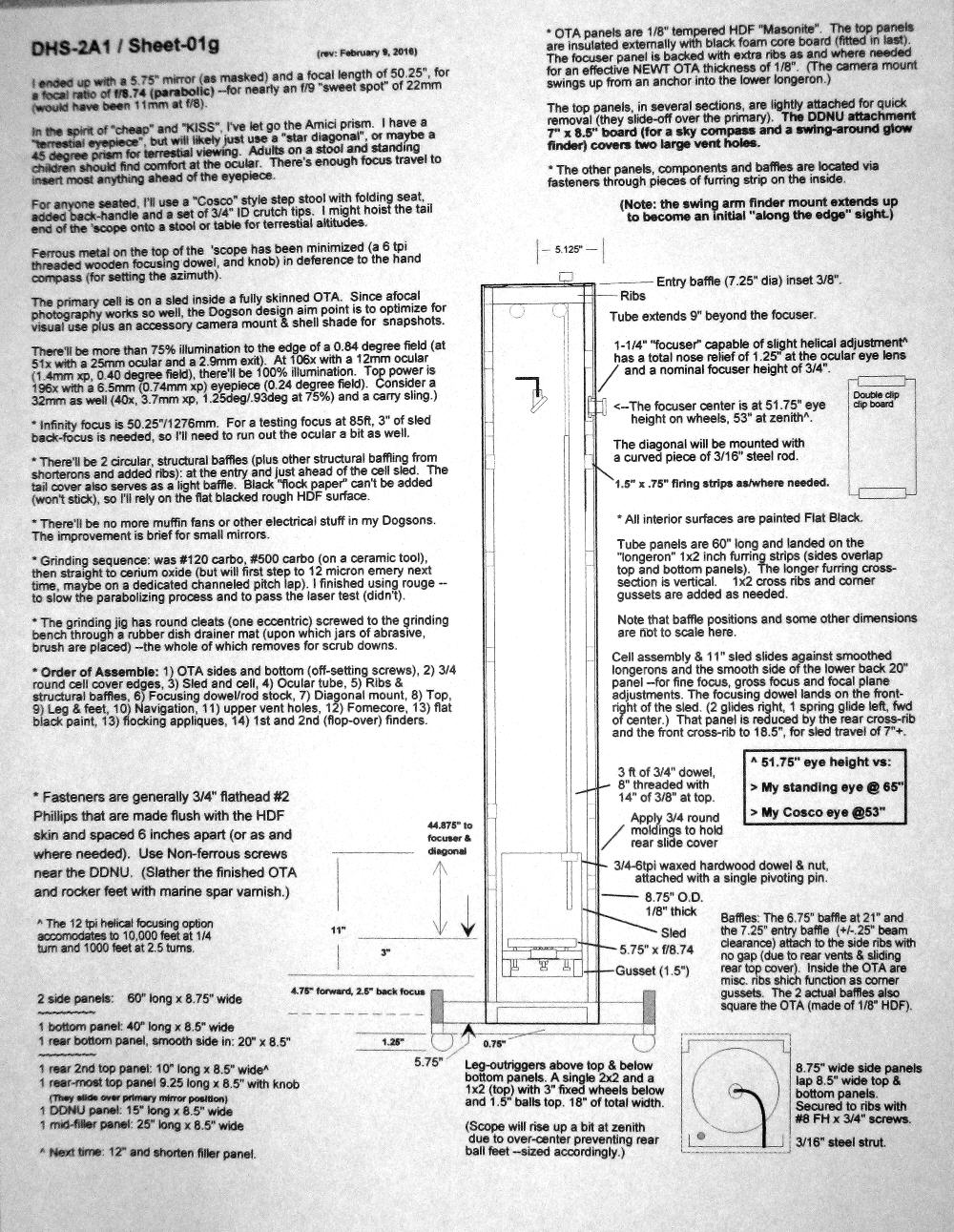

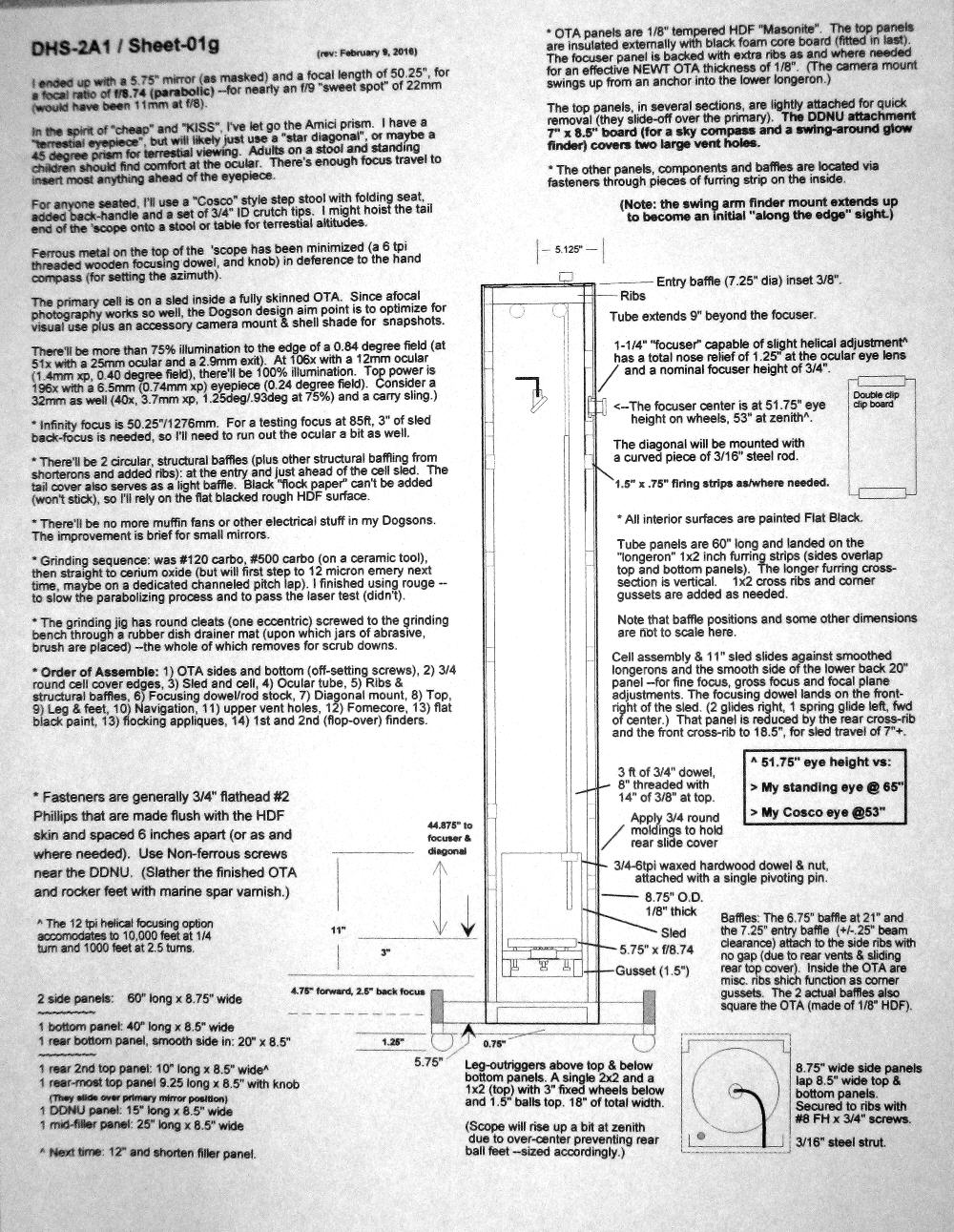

* Here's the main page of my as-built

drawings for Dog-2 (click to enlarge):

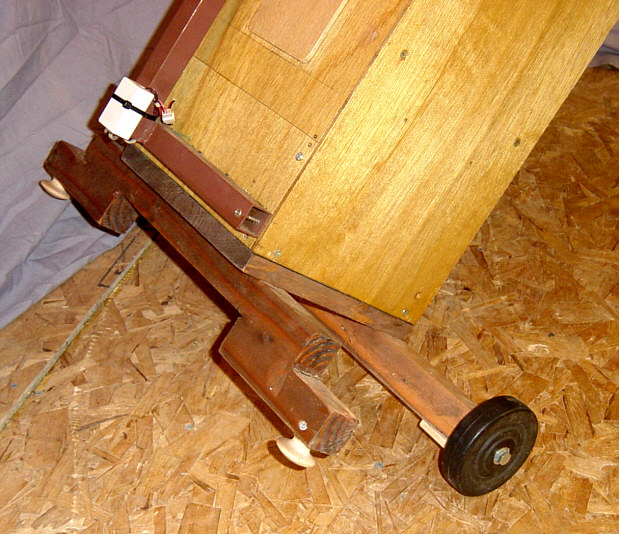

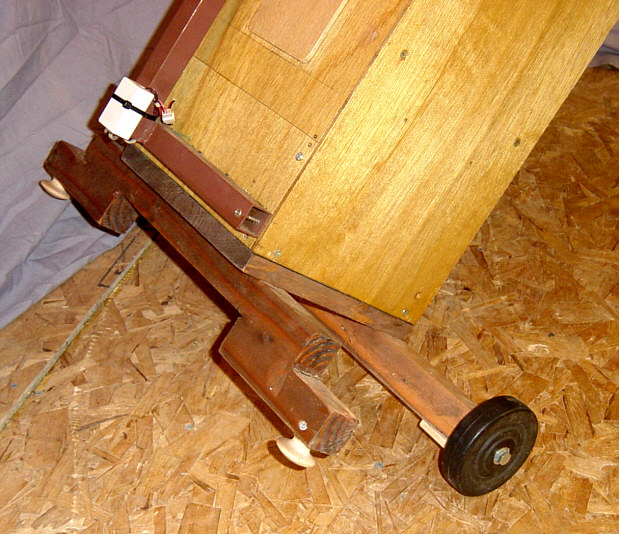

"Dog-3" will probably follow a simpler construction

plan, but it will still be about 6 inches by f/8

(Since this plan and these photos, I've gone to 5"

"wheels" (which only "turn" with the 'scope) plus

one inch extensions under the over-center balls --for

better ground clearance on rough terrain.)

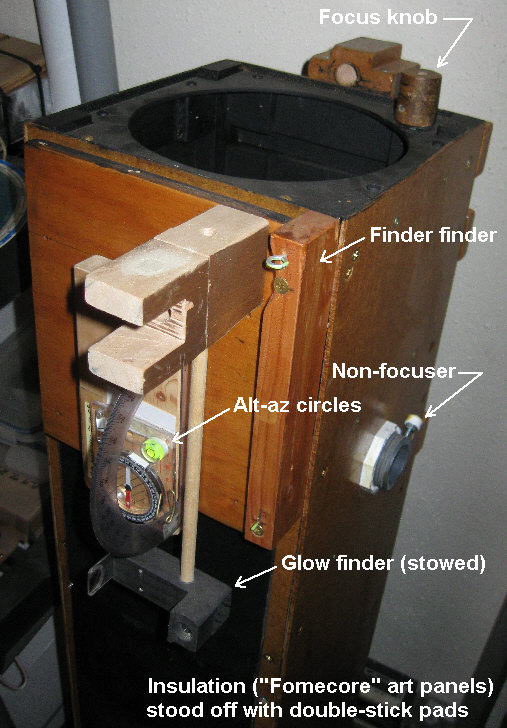

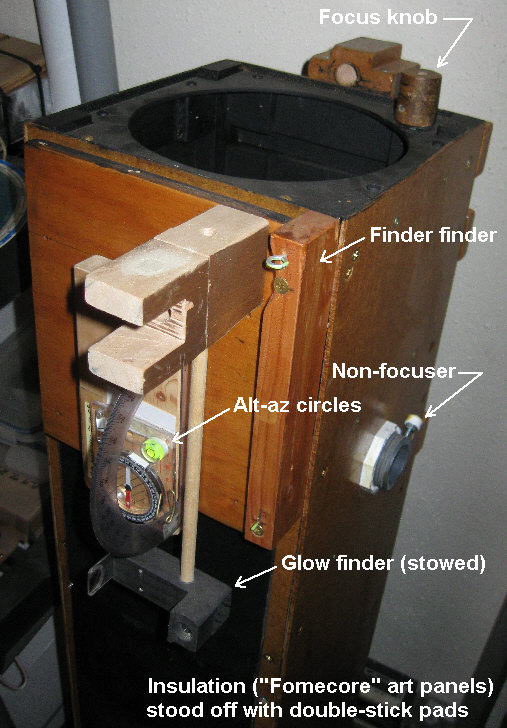

(Click these images to enlarge them.) (Earlier

version.)

* Let's address the Dogson design/concept's deficiencies

(that

I'm aware of):

* Let's address the Dogson design/concept's deficiencies

(that

I'm aware of):

~ Chief among them is low altitude

(below 30 degrees) sky and terrestrial observational performance. You can

hoist the butt end up onto a stool or table, but then the balance and vibration

aren't good.

~ Dog-2's low altitude accommodation

was somewhat designed around a Cosco brand step stool that we own. With

added crutch tip feet (the small original feet sunk into the ground), it

seemed ideal to use with this scope --sitting, small kids stepping up,

"butt hauling" (with the seat flipped up) for the range of 15 to 30 degrees,

and down to zero with the alternate fore-leg.

~ While (screw) jacking the Dogson

up and down in altitude goes swimmingly, some won't like turning this 'scope

in azimuth --with its non-turning wheels dragging in the dirt (and there's

a wee bit of backlash to compensate for).

~ By today's strut and string 'scope

standards, at 30 pounds it's heavy for a 6 inch telescope, though maybe

not when compared to other long focus, closed tube scopes.

I had on loan a typical, commercial, 8 inch Dobson (an

early Orion). The tube assembly with mirrors weighs 24 pounds and the base

weighs 25 pounds. Were I to scale my Dogson up to use an 8 inch mirror,

it would weigh 71 pounds and I'd need to stand on a step stool at times.

(This old Orion's tube is only 9 inches inside diameter and a trim ring

at the mouth reduces that to 8-3/8 inches, so this scope should have been

a bit larger and heavier --as are Orion's later 8" Dobs.)

I had on loan a typical, commercial, 8 inch Dobson (an

early Orion). The tube assembly with mirrors weighs 24 pounds and the base

weighs 25 pounds. Were I to scale my Dogson up to use an 8 inch mirror,

it would weigh 71 pounds and I'd need to stand on a step stool at times.

(This old Orion's tube is only 9 inches inside diameter and a trim ring

at the mouth reduces that to 8-3/8 inches, so this scope should have been

a bit larger and heavier --as are Orion's later 8" Dobs.)

~ The Dogson is not a scope for

swinging about and earning your Messier certificate. It's for picking and

finding a target/object, studying it, and maybe shooting an afocally

coupled snapshot (if the object is bright enough).

~ So far, I can't think of any way

to make this "stick-in-the-mud" telescope track.

~ Then there's the

"Dobson hole": that difficulty when observing near the zenith, since aiming

at and following a star with an Alt-Az mounted 'scope requires nearly a

180 degree swing-around in azimuth. However, the Dogson design lends itself

to a recent solution demonstrated by Mel Bartels: the "Alt-Alt-Az" mount

(see the February 2019 issue of Sky & Telescope for its Workbench article

by Jerry Oltion). Instead of rigidly mounting the Dogson's over-center

back feet to the OTA, the cross-bar might instead be attached at its center,

via a lateral rocker bearing (with limited range and considerable, adjustable

friction). The downsides of doing so:

> Don't let go of the OTA until its foreleg is securely repositioned and

planted.

> The DDNU (setting circle platform)'s calibration is lost when resorting

to secondary altitude travel. However, the assumption is that the observer

is already close to or tracking the quarry --and/or: for the experienced

astronomer, the sky is his/her chart/program and no recourse to co-ordinates

is required.

* Dogson Advantages:

~ As a one-hand lift, one-piece

telescope (not counting a stool and kneeling pad), you can take it and

go (the separately stored mirror already having been slipped into place).

(I only "go" out into the side yard of our home.)

~ At astronomical altitudes (30

degrees and above) the OTA/tube is itself two parts of a steady tripod

to the ground. There are no vibrations, no shaking when you adjust the

focus, and no balance problem when you use a large eyepiece or mount a

camera. If you're tired, rest an arm on the scope.

~ By using the Cosco step stool/chair

or a typical plastic garden chair (which has about an 8 inches lower seat),

an adult can comfortably observe from about 45 degrees of altitude to the

zenith. For the range of 30 to 45 degrees, an adult who's able to use a

kneeling pad or a low stool is accommodated.

~ The mirror is securely held captive,

but easily removed with a single thumbscrew --such that it is convenient

to store the mirror at outside temperatures (face down in a cheap, desiccated,

air

tight container). There's a mark on the mirror's periphery so I can

always re-install it the same way.

~ The primary mirror cell rides

on a sled which can be moved to adjust fine focus and/or to accommodate

gross prime focus changing accessories (like maybe an erecting Amici prism

or a Barlow fore-lens) and to accommodate close subjects (down to 100 feet,

and more such accommodation can easily be designed into the Dogson).

This gross focus adjustment range can also make up

for a maker's mirror that fell short or long of its target focal length,

without having to bore another focuser hole.

~ The "focuser" also focuses a bit

--helically, possibly to estimate distances in the 1000 to 10,000 foot

range.

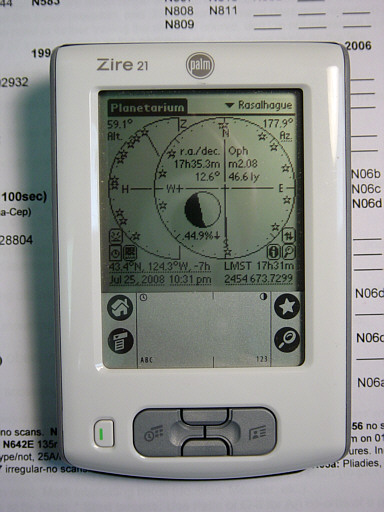

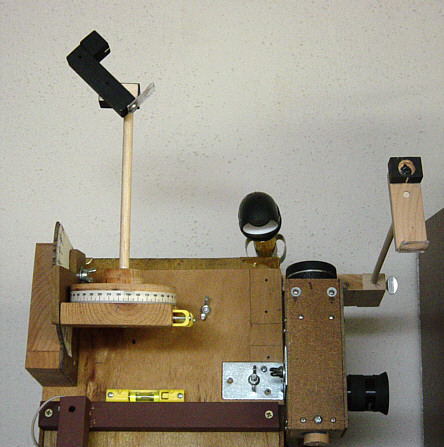

~ Despite not having a rocker box,

this Dogson does have setting circles

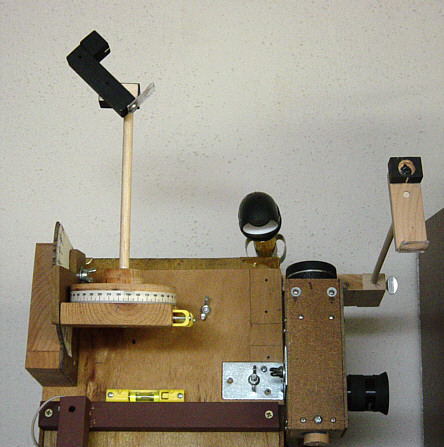

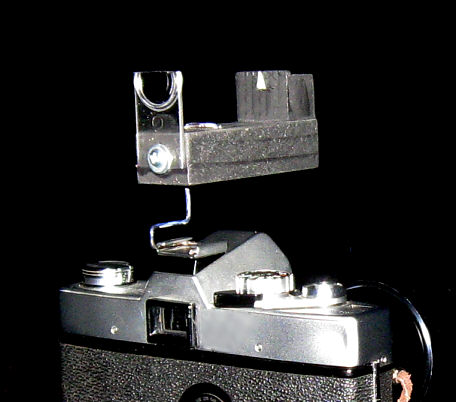

~ It also has a swing

out (and swing around to the other side, if desired) lightweight finder

--

~ --plus a swing-up camera mount.

~ Since the tube is square, it's easy

to mount accessories and features like those black "Fomecore" top-side

insulation panels, internal baffles, the cell sled,

sled tension arms, the secondary strut positioning "float

block", a plumbing parts

focuser, a slide-off mirror

access

panel, a frame attached

Dog leg and feet,

a swing-out finder and the DDNU navigation platform.

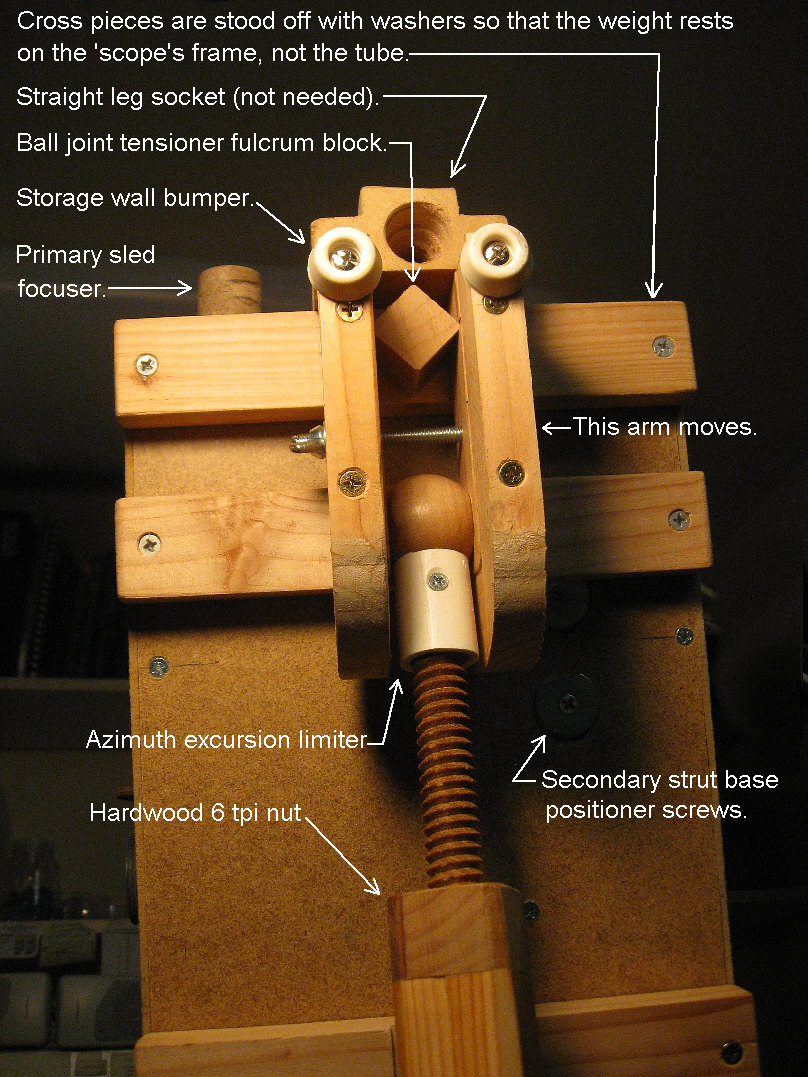

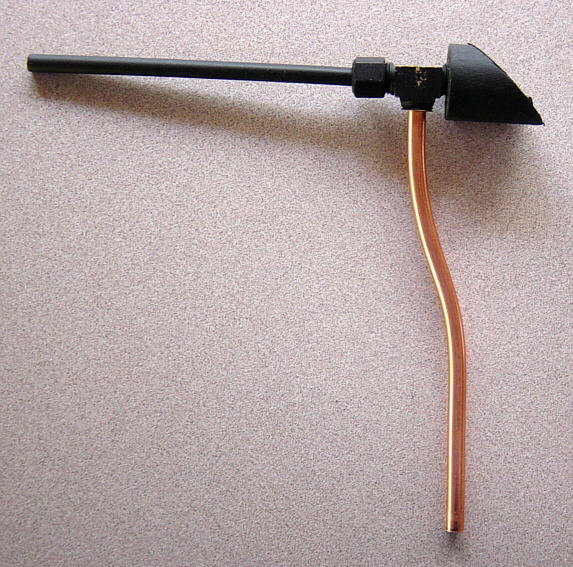

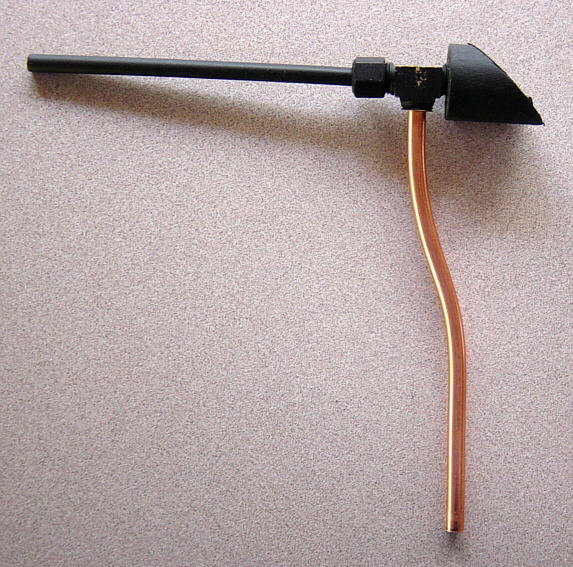

Focuser detail

(The set line and bumper piece is for laterally positioning

an afocally coupled, swing-up hand camera.)

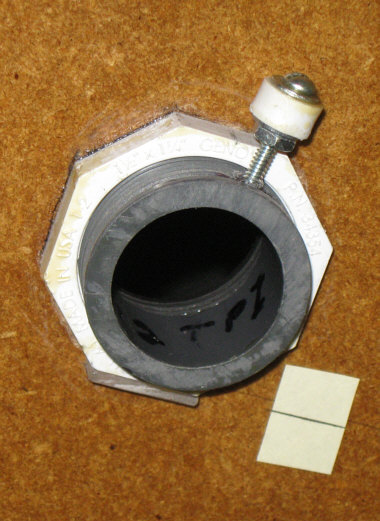

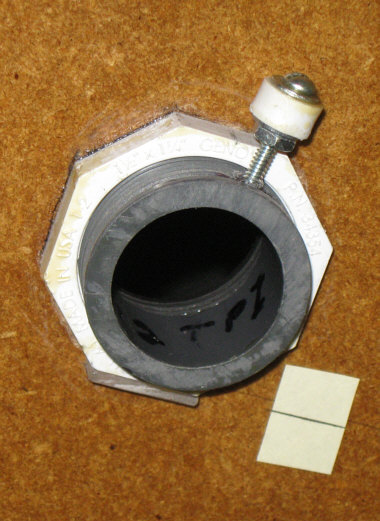

This limited helical focuser is cobbled from plumbing

parts (you can see the inside detail here). It can

hold the waist banded, short barreled 32mm Celestron eyepiece in the below

image. However, except for range estimation (1000 to 10,000 feet), such

slow focusing adjustment isn't needed. Given smooth barreled eyepieces

and the cell-sled approach to primary focusing, one can easily do fine

focusing with less than parfocal eyepieces by simply turning and push-pulling

them in a simple "eyepiece holder" like the below pictured plumbing item:

a 1-1/2" to 1-1/4" ABS, male trap adapter (under $2, and thanks to Richard

Berry for the suggestion). The nut adjustment and washer produces any desired

degree of buttery smooth grip upon a standard (smooth) eyepiece barrel.

(Simply add thin O-rings to your eyepieces to make them approximately parfocal.)

A few 1-1/4 inch choices

Rack and pinion focuser, Plumber's delight eyepiece

holder, Smooth barrel eyepiece, Celestron's waisted 32mm eyepiece

The traditional focuser at left is usually fitted so

as to allow an inch of inward travel. As such, and with an eyepiece fully

seated, the top of its tube stands an eyepiece 4 inches off of a round

tube, and 4-1/4" off a square tube. Using a low profile helical or friction

focuser like that ABS plumbing item can bring the eyepiece in to only an

inch and a half (leaving a bit of inward travel), which in turn allows

a significant reduction in diagonal size/obstruction, diagonal weight and

potential vibration problems. (Again: that plumbing item is a no-go with

a waisted eyepiece barrel.)

Modern Times:

Modern Times:

* Yes, I'm aware of "goto" 'scopes and the amazing

"Safari" ($20 --!) application for i-Pads --which I've played with for

a few minutes, and which affordably turns any telescope into a goto instrument

--or buy a long focus optic for the i-Pad, which then itself becomes a

navigating astrophotographic telescope --!-- (but you might then want to

mount it onto a good tripod).

* Most everyone we know, young and old, has a hand-held

computer/cell phone/Internet device --except ourselves. My understanding

is that once you've acquired an I-thing (used ones are affordable or free)

with GPS and inertial/gyroscopic capabilities --and have downloaded a Safari-like

sky program, it can then be operated (sans any updates) without a communications

contract. But --the Luddite in me says: "whoa".

* But what do I know? Our great-grandchildren had to

tell us about WiFi a few years back. We stood there like amazed bush people

as they sucked the Internet out of thin air. We only pack a bottom-feeder

CDMA Tracfone (under $10/month) for hello-goodbye voice and have no Internet

access at home --which would cost us $55/month --more than water and sewer!--

unless part of a $90/month "bundle". (We remember $10/month for an Internet

connection.) So instead, we use a pair of Chromebooks

to cadge free public WiFi.

Some of the "passions of our times" (like posting this

page to the Internet) we must share --even embrace (and ain't HTML grand?),

but I feel alienated from things that are price fixed and far beyond my

understanding. (This is really more about my own struggles here with modernity

--than any retro advocacy.)

The Mirror

The 6 inch mirror that I made for my "Dogson-2"

telescope has only been my 2nd time at grinding and polishing in 60 years.

My first mirror was an 8 inch x f/10, which I finished to a spherical figure.

To begin: * If the back of your

blank isn't smooth and clear, make it so --by grinding with #120 and then

#500 grit against flat glass or ceramic tile. Follow that up with some

sleazy polishing technique --like #500 grit against a plastic tool --whatever

works to make it transparent.

* Next: put a good 45 degree bevel

(or "chamfer") around the peripheries of the back and the face of the mirror.

Yes: you'll be initially losing some diameter --as much as 1/4 inch (1/8"

bevel), but you get some back as you grind, and you want enough bevel so

as not to be doing it twice. I used a typical, traditional, two-sided (rough

and fine), carborundum sharpening stone --and the fine side seemed fine

enough. (This beveling work takes a while.)

~ When cleaning my finished, polished

mirror in preparation to send it in for aluminizing, I was unable to simply

wash off a ring of cerium oxide (polishing agent) which was crusted onto

the bevel. I had to go around the bevel again with the carborundum stone

--holding the stone such that I could not possibly scratch the mirror.

Grinding: The grinding part of this

project was pretty straight forward, plus I benefited from good advice

by my circle of astronomy/ATM friends.

Grinding: The grinding part of this

project was pretty straight forward, plus I benefited from good advice

by my circle of astronomy/ATM friends.

I also gathered what I could from the literature in

our library and summarized it:

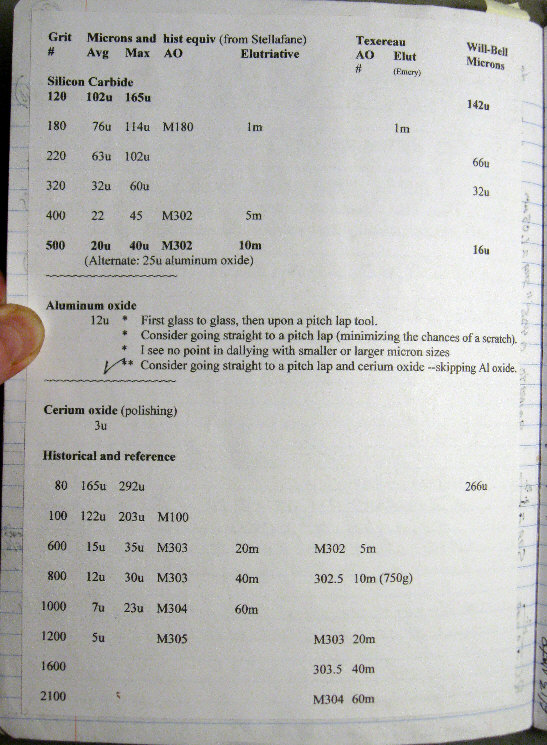

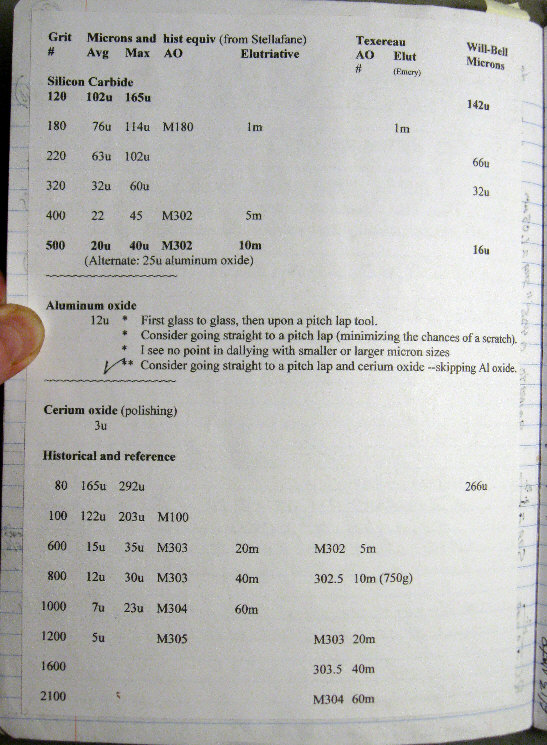

* Unlike 60 years ago when I made my first mirror, and

per suggestions from others in my astronomy e-group, I short-circuited

the little incremental abrasive steps by starting with #120 grit (102 micron

average, 165u max), then #500 (20 micron average diameter, 40 micron max

--quite a jump) --and straight to polish after that. The old timers didn't

have today's "micron" grits and generally went from #600 grit (12u average,

30u max) to polish. I wanted to find out how tough it is to polish out

#500 grit pits --with today's advantage of using cerium oxide.

* Unlike 60 years ago when I made my first mirror, and

per suggestions from others in my astronomy e-group, I short-circuited

the little incremental abrasive steps by starting with #120 grit (102 micron

average, 165u max), then #500 (20 micron average diameter, 40 micron max

--quite a jump) --and straight to polish after that. The old timers didn't

have today's "micron" grits and generally went from #600 grit (12u average,

30u max) to polish. I wanted to find out how tough it is to polish out

#500 grit pits --with today's advantage of using cerium oxide.

Answers:

~ The rough and fine grinding both

went fast --maybe too fast for good control. I spent more time gauging

my progress (ended up using automotive leaf gauges and a truly straight

[hard to find] steel rule for the sagitta) --

~ --and trying to judge when #500

pits had vanquished the #120 pits. (Which was fairly easy, after I made

a glass microscope slide with #120 grind on one end and #500 grind on the

other --for microscopic comparison.)

~ You can switch to "wet testing"

the mirror (plain water is best) by reflection (an AA battery flashlight

next to your eye) shortly after starting the #500 grit grind.

~ Be very sure to do the "pencil"

or "felt tip marker" test for contact --before calling it quits with your

finest fine grind. (Simply mark up the mirror, then see if a few strokes

cleans your marks off evenly.)

~ Yes: it is plenty tough to

polish #500 grit pits out of Pyrex --something

like 20 hours to pass traditional microscopic inspection. The alternative

is to use a final, very fine grind with "micron grit" --maybe 12 micron.

However, this is the point at which your mirror is most vulnerable to getting

scratched (one of the reasons why I skipped using micron grits). Next time

I'm going to try following the #500 grit with 12 micron grit on a dedicated

pitch lap --which "will not scratch".

* There were many little questions and decisions:

~ How much grit per "wet" (1/8th

teaspoon);

~ How long is a "wet" (go by ear,

and you can add drops of water to extend it a bit).

~ How hard to bear down during rough

grinding (as hard as you can comfortably sustain without getting sloppy,

which was about 20 pounds total pressure and mirror weight for me).

~ How wet is a wet (sluice off the

tool and mirror in your plastic bucket, leaving both wet).

~ How wide & long is the "hogging"

stroke (what you're comfortable with -maybe "4/5ths".

Don't tip the mirror.)

~ How close to the RC (radius of

curvature) should I rough grind (1% long, since the "1/3rd

W" "maintenance stroke" pretty much stops RC progress when you need

to (during fine grind or polish, and assuming the use of a polishing cradle).

You can "hog" #500 grit until the focus is about 0.5% longer than your

target.

* Again: For a more complete background on ATMing,

follow this link:

https://stellafane.org/tm/index.html

Polishing:

Polishing:

* I repeatedly experienced the common problem of a

blankety-blank "turned down edge" (TDE) plus it

had a stubbornly oblate figure --even with an undersized lap (MOT).

I've read and heard that a TDE is especially common for beginners and for

those who make longer focus 6 inch mirror --for over 100 years, and maybe

for 300 years. I think it's time to get a better consensus as to what

causes a TDE and what doesn't.

** For sure: since the mirror's figure at the edge

of a mirror must "go around the corner", there will always be a bit of

TDE. One ATMer routinely flats and frosts it with fine grit, then paints

it flat black. Many others, some commercial, routinely mask off a wee bit

of TDE --perhaps using a metal band with a rolled edge. I mask

the edge with a black paper collar and a cut-to-pop-in-fit O-ring (thickness/diameter

as needed).

Fingers are often pointed at soft pitch laps as the

TDE culprit and one can imagine the mirror's leading edge plowing into

soft pitch. Mel Bartels and

others, however, can work with a relatively soft lap and not end up with

a serious TDE. Also, the periphery of my mirror was the last to polish

out (which is typical), so the TDE didn't develop because I was knocking

down the edge --but because I was deepening the slope of the central zones

(despite that it somehow remained oblate, overall), and/or the polishing

action wasn't getting to the edge (duh: since the edge spends half the

time over-hanging the lap).

Never-the-less, I slowly came to the realization that

my pitch was indeed too soft, which is at least a nuisance in that the

lap needs frequent trimming.

It also dawned on me that we needed a much better

way to gauge pitch hardness. Traditionally, one simply bends a small

piece or pushes his/her thumbnail into a sample, but touching, holding,

or the very work of pushing your thumbnail into it will heat and sharply

soften the pitch. (In India, ATMs try chewing a piece -!- but before you

write them off as primitives, I also have an account of that being the

practice in a pre-WW-2 optical lab here in the states.) Consequently, I

took a long detour in order to nail down the

hardness of

my pitch --against temperature.

While I suspected that I'd not have developed such

a horrible turned down edge with harder pitch, I first went (by stages)

to a 17% (1 inch) undersized lap (polishing with

mirror on top = MOT) to see if that alone (using my rather soft 58 minute

[plunge test] pitch lap) --might roll back a turned

down edge --without producing other problems. It didn't, and I've gotten

the impression that undersized and otherwise "mutilated" laps are a zone

problem making bad idea.

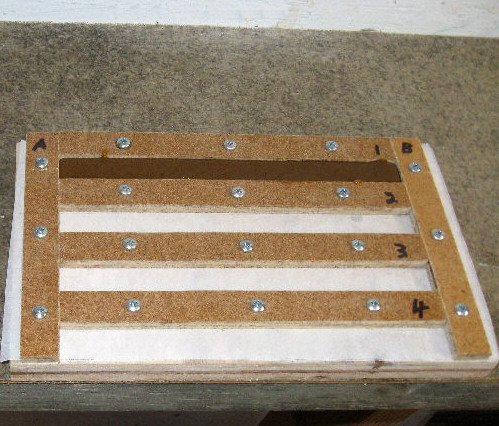

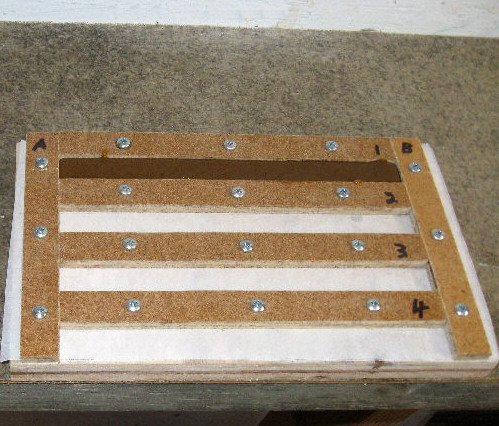

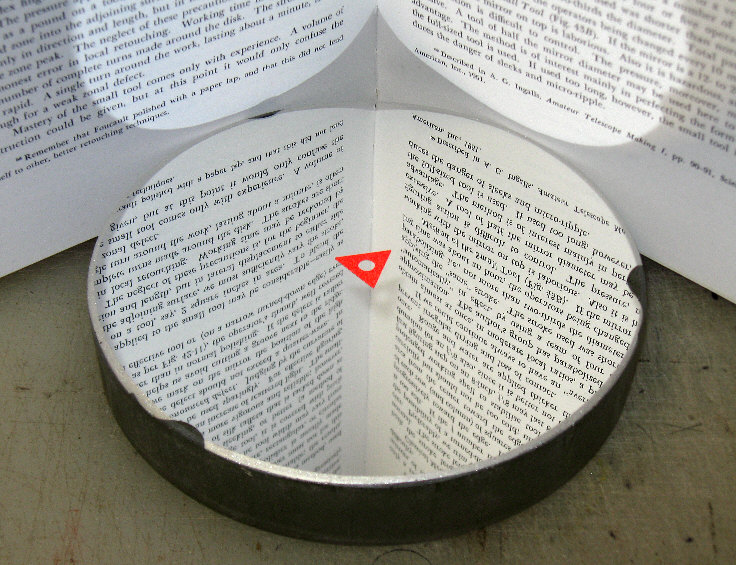

My pitch strip mold and grinding tool, marked for

a 6" lap with 1" tiles

--and the failed undersized lap effort (click

to enlarge)

* I eventually settled on using somewhat soft (166

minute plunge test) pitch --which is about the same viscosity/hardness

as (brand name) "Gulgolz-64", and I reduced my TDE with a 4/5th "W stroke".

Polishing Speed and Pressure

(11/8/2015)

I have to force myself to go slow and not bear down when

polishing. Developing good contact and drag (which "micro-faceted" tile

faces help) --has a natural effect of slowing the stroke speed. It does

seem that, to get the smoothest and most careful results, minimum pressure

and a slow rate of mirror travel (MOT, a maximum average

of 8 inches per second) are important.

The negative consequences which ATMs have experienced

by polishing "too fast" and the "strokes per second" or minute advice we

get on that matter must also be weighed against mirror size and stroke

length --since (obviously) a "1/3rd" W stroke per second with a 12 inch

mirror requires moving it twice as far per second than with a 6" mirror.

I've decided against blaming inertial tipping/plowing

and drag heating (unless polishing squeaky dry), but it seems intuitive

that if the "give" of pitch isn't fast enough for cerium oxide particles

to yield (when they snag into the pitch), then they might start to tumble

--in the fashion of grinding particles.

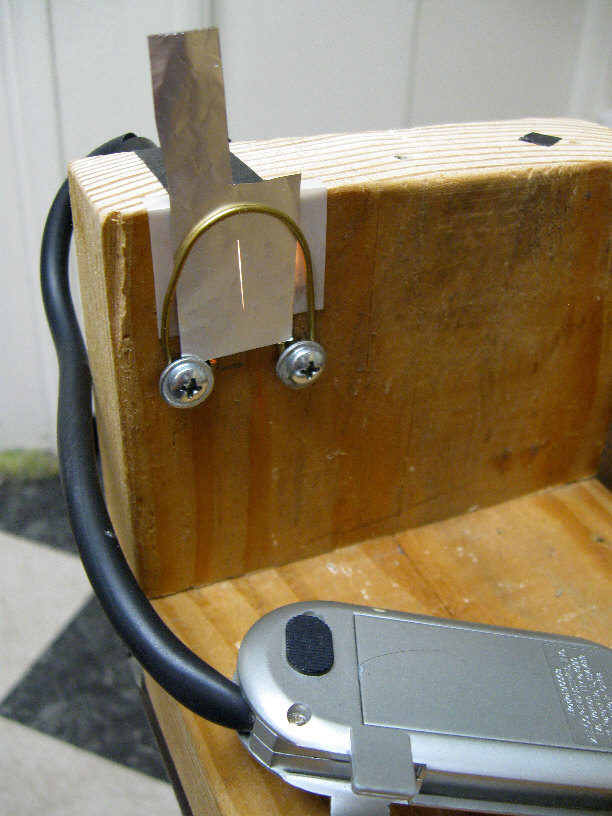

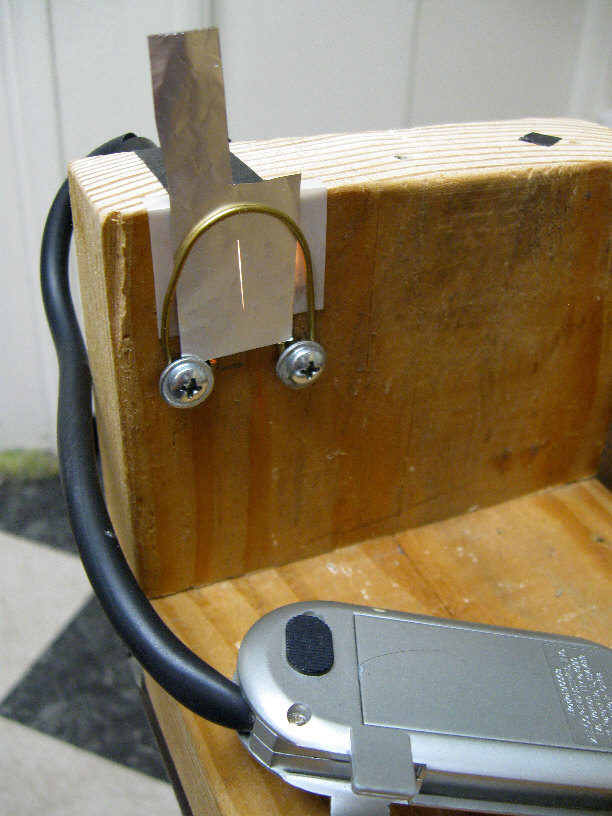

The Pitch

and checking the "hardness"/viscosity

(Click on these images to enlarge them.)

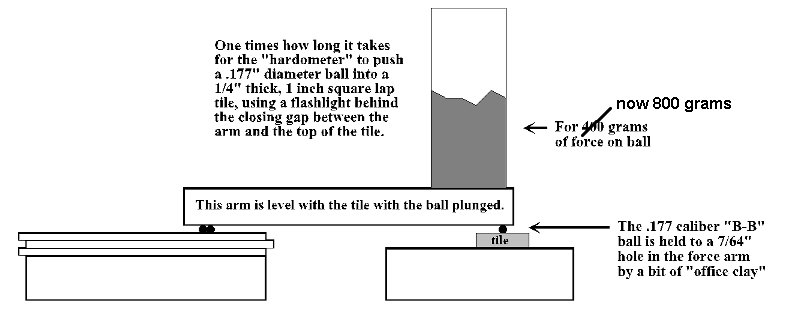

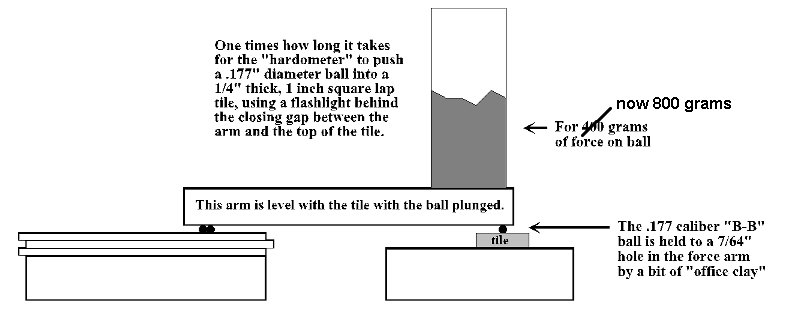

The 1/4" x 1" square pitch tiles are kept in a 68 degree

Fahrenheit water bath until tested and the room temperature (or that of

an enclosing box) is maintained at 68 as well (20 degrees centigrade).

What you see is a hardwood arm with two glued in BB bearings in the back

and a single test BB in the front --captive and located by a 7/64 inch

hole and a bit of "office tacky clay" (wonderful stuff). I added enough

lead shot to that tube such that the scale read 800 grams (with the arm

level).

For more about these tests, see here.

For more about my approach to making a small pitch

lap (ala Jean Texereau), see here.

Not shown is the box I put this rig in, the ice chest

and 12v muffin fans which supplied and circulated cooling air, the HVAC

household thermostat, DPDT relay, 12 volt DC supply, nor the small 120v

lamp and dimmer switch which adjusts the rate at which the temperature

is brought up again. A programmable digital thermostat (the affordable

Lux brand) and a Coleman Peltier effect 12V cooler would have been better

choices, but I tend to use what's at hand.

Not shown is the box I put this rig in, the ice chest

and 12v muffin fans which supplied and circulated cooling air, the HVAC

household thermostat, DPDT relay, 12 volt DC supply, nor the small 120v

lamp and dimmer switch which adjusts the rate at which the temperature

is brought up again. A programmable digital thermostat (the affordable

Lux brand) and a Coleman Peltier effect 12V cooler would have been better

choices, but I tend to use what's at hand.

However: one can simply use the normal temperature

and environmental controls of the room the illustrated apparatus is located

in, making sure to keep the air moving for uniform temperature. The below

graph will help you compare a single plunge time that you've clocked

against my measurements (at least for the two brands of pitch I've tested)

such that you don't have to worry about what temperature spot on the graph

you use --just temperature uniformity (a fan and mid-day) and wait for

the pitch under test to arrive at a uniform temperature.

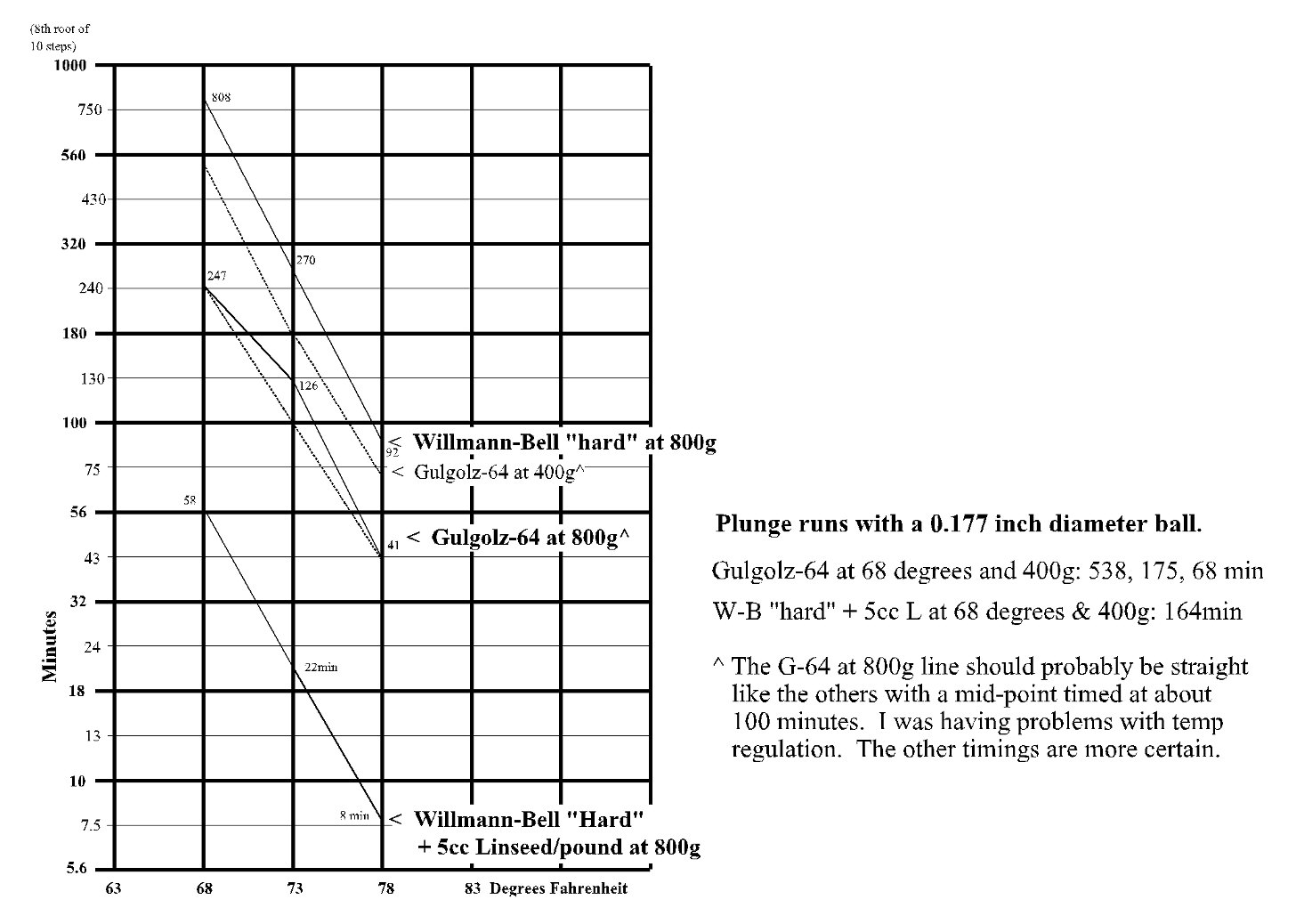

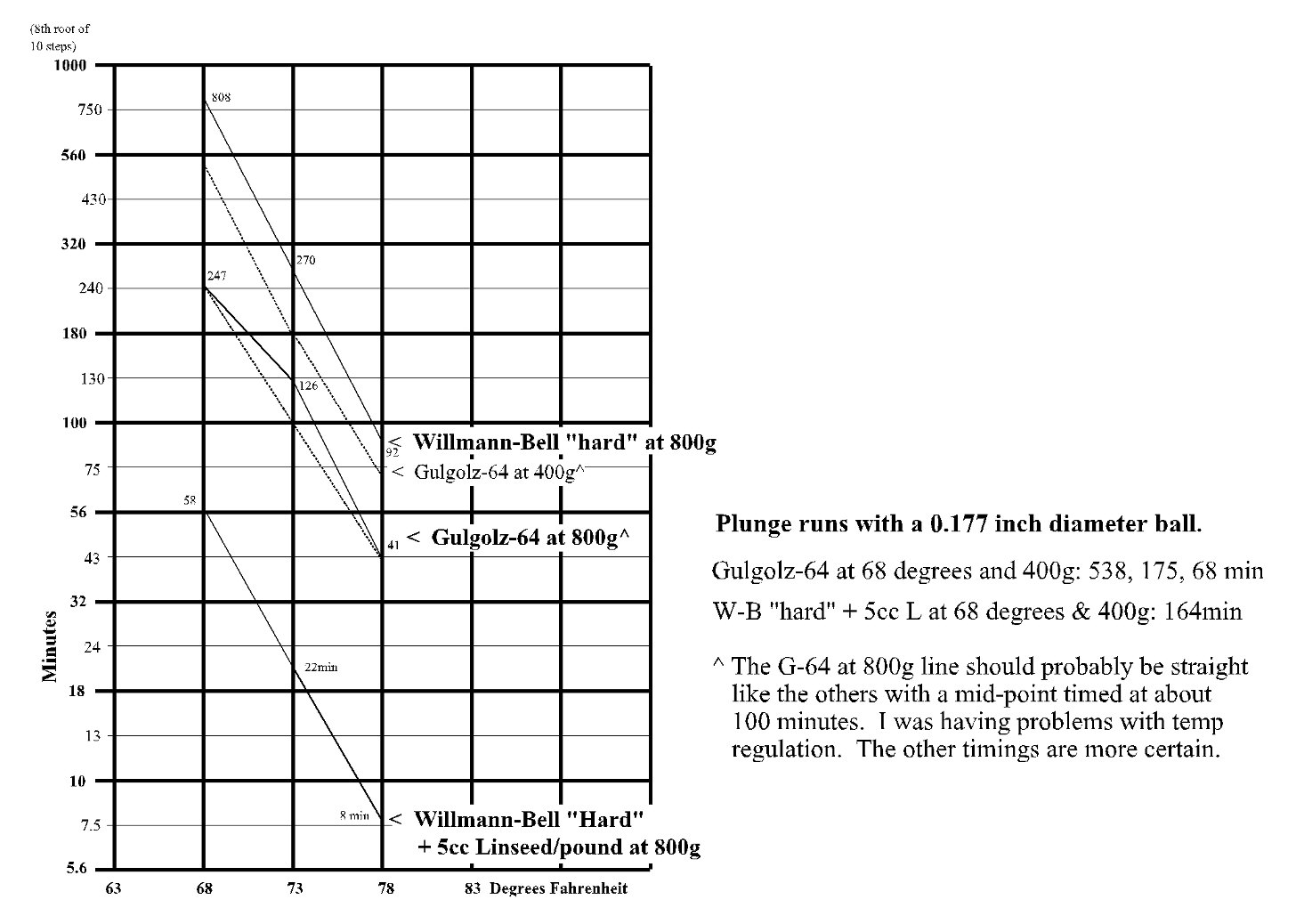

* Optical pitch is a rather viscous substance. My plunge

times for both Willmann-Bell "hard" pitch and Gulgolz-64 were running to

12 and 9 hours --at 68 degrees Fahrenheit with 400 grams of weight force.

Consequently, I switched to lead shot and doubled the plunging force to

a weight of 800 grams. That didn't simply halve the initial plunge times,

since the work performed in plunging the BB ball contributes to the local

temperature of the pitch. Results will always be peculiar to the test method

used, so try to replicate my test rig, develop methods and graphs of your

own, or use the test rig published in later editions of Jean Texereau's

book (see next item).

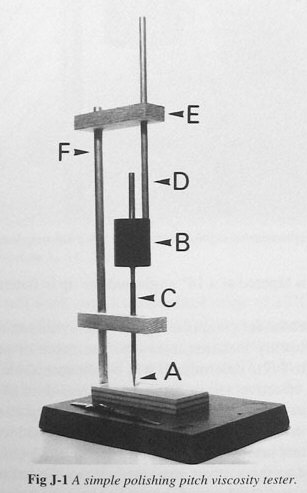

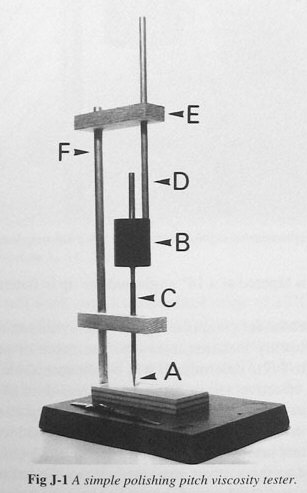

Update (10/05/2014): My 1957 copy

of Jean Texereau's "How To Make A Telescope" advocates the old thumbnail

pitch hardness test, but thanks to Jerry

Oltion, I've been alerted that later editions include simple plans

for making a pitch hardness/viscosity test rig:

--which drives a kilogram weighted (total weight at the

point), steel rod into a polishing tool mounted pitch square for a period

of 5 minutes --after which the penetration depth is measured. The acceptable

depth range for mirrors between f/6 and f/12 is 0.02 to 0.24 inches (0.5mm

to 6.0mm) --at your work room temperature. The hardness goal is set at

.07 inch (1.8mm) of travel depth after 5 minutes. (Deep dish mirrors in

the f/3 to f/4 range have proven hard to work unless softer pitch is used

--perhaps a 0.31 penetration depth --at your work room temperature.)

--which drives a kilogram weighted (total weight at the

point), steel rod into a polishing tool mounted pitch square for a period

of 5 minutes --after which the penetration depth is measured. The acceptable

depth range for mirrors between f/6 and f/12 is 0.02 to 0.24 inches (0.5mm

to 6.0mm) --at your work room temperature. The hardness goal is set at

.07 inch (1.8mm) of travel depth after 5 minutes. (Deep dish mirrors in

the f/3 to f/4 range have proven hard to work unless softer pitch is used

--perhaps a 0.31 penetration depth --at your work room temperature.)

The penetrating tip is tapered to 14 degrees and its

tip is flattened back to a width of 0.04 inch (1mm), the details of which

will be found *here*

on Jerry's pages, since he built a Texereau tester.

Jerry also checked some new Gulgolz-64 pitch, finding

it to fall 0.021 inch at 68 degrees F. Earlier,

he'd sent me a sample of the same pitch and it corresponded to 247 minutes

on the

chart below when using my rig. That happens

to be the hardest pitch Texereau recommends for polishing and figuring

medium to long focus mirrors (at a work room temperature of 68 degrees

Fahrenheit).

Judging from my chart and the one in Texereau's newer

editions, this pitch would remain usable at 80 or so degrees --but I couldn't

recommend that for long focus mirrors. Texereau's pitch hardness "goal"

would be about 78 minutes on my chart, but I ended up working with 166

minute test pitch (corrected to 68 degrees F., or 20 degrees centigrade

--which is the normal lab standard.)

** When doing hardness tests, it's very important to

know

what the temperature of your pitch is. It's very unlikely to be

at room temperature if that temperature has changed in the last hour, or

if you've handled the pitch. I soaked my test tiles in a temperature monitored

bath (a glass of water at room temperature) before testing and transferred

the test squares/tiles with tweezers. Again: hardness changes drastically

with temperature.

** Since the flow rate of pitch is affected by thickness,

tile size, and clear channels between, your pitch tiles should be made

to a standard --and that might as well be the 1 by 1 by 1/4 inch tile size

assumed here and by Texereau. They'll seem harder as they get thinner.

(Never allow the channels to close.)

Test methods compared:

* The most obvious difference between my test method

and Texereau's is that his gauges depth, while mine measures time --both

graphed on a logarithmic "Y"/ordinate axis. I think my method is a better

way to go, since standard tiles are only 0.25 inches thick, whereas we've

(hopefully) got plenty of spare time.

* A major advantage of the Texereau test is that the

steel rod can be expected to conduct heat away from the worked point of

penetration, thus more truly representing pitch viscosity/hardness at ambient/room

temperature. However, if you decide to capitalize on that by (say) making

the rod out of copper, your results might be at some small variance from

Texereau's.

Aside from convenience, I don't think that the tile

being mounted on a glass tool is a factor in carrying away heat since neither

the pitch nor the glass is very conductive.

* To somewhat compensate for the confinement of heat

(to the B-B and point of contact) when using my tester, I kept a fan running

on it and used rather long run times (first at 400 grams, then 800 grams

of force --and I suggest that you use no more).

* I suspect that a lot of the advice we read about

pitch and laps is based on several times reheated/recycled pitch, which

then ends up pretty hard. However, the beginner starts with freshly delivered

pitch, some of which is impossible (judging from the Willmann-Bell "hard"

pitch I purchased) to heat to a pouring temperature without a lot of froth.

Perhaps beginners, having been soundly counseled against "boiling" the

pitch, consequently end up with a poorly poured, soft lap. (The Gulgolz-64

product I tested did not foam when heated to pouring temperature --a bigga

point in its favor.)

My approach to Willmann-Bell's "hard" pitch was to

first slowly heat fresh pitch past the pouring temperature (I reached 230

Fahrenheit, and I've seen 257 degrees suggested), drop back to my pouring

temperature (205) and stir down the foam for a fairly bubble free pour.

(It's not to worry about little bubbles. They make good micro facets.)

* Judging by the rudeness of traditional hardness tests,

I suspect there's a wide range of hardness which will work well, especially

for small, long focus mirrors. (Again: deep mirrors are said to need softer

pitch.)

* Making a batch of pitch harder seems to require either

adding rosin or enough heat for sustained "ebullience": the frothing off

of volatile components in the pitch --which begins below the 212 degree

boiling point of water with fresh W-B pitch, but such frothing/foaming

tends to be less in once heated pitch --until you exceed the last temperature

reached. (I've also seen ATM advice specifically warning against any foaming,

but -again- that might be based on recycling long since foamed off pitch

at reasonable pour temperatures.)

** Please go slow, use low electric heat and

be prepared to smother a fire. (Don't use water!) **

* I used linseed oil to soften pitch. It's less volatile

than turpentine, and you need only a few milliliters/cc per pound of pitch

to make a big difference. The downside: it's then tough to harden it again

with heat.

* I used a candy thermometer, which wipes pretty clean

when hot. Later (burner off and away from the stove) you can wipe the rest

of the pitch off with a little mineral spirits (paint thinner) and a paper

towel.

* My W-B pitch was pour-able at about 200 degrees,

so I stopped heating it at 230, stirred down the foam/bubbles, and took

it off the kitchen range at 205 degrees.

~ However, you

shouldn't need to take the temperature of your pitch, especially

when using the Gulgolz brand. Just slowly heat it to an easy pouring temperature.

** Again: go slow when adding heat and

do

not leave the stove unattended.

*** After many tests and reheatings, the bottom fell out

of one of my several Mason jars --which incident holds potential to become

a disaster. Since you don't have to experiment with a dozen different blends

and heat treatments of pitch like I did, skip the foil and jars. Just buy

a dedicated pan from your local Salvation Army store.

Hardness increases as temperature drops --and at a

steep rate.

The average of these rates is +22% per -degree F.

(click to enlarge)

* After much experimentation, I ended up with a batch

of pitch that plunge tested at 166 minutes (corrected to 68 degrees). I

can't tell you how I got to that hardness (too many detours and reheats),

but you can get there with W-B pitch by adding very little Linseed oil

(maybe 1cc per pound) --or: simply buy some Gulgolz-64 (which is said to

have conditioners against chipping) --which checks out at about the same

hardness.

The Pitch Lap

This is far from a complete overview of the pitch lap

and polishing --but it might hold few useful items.

* In view of the above graph,

simply raising the temperature in my (small) mirror shop let me do the

initial lap pressing ("cold pressing"^) in 3 hours. Another time it took

9 hours at about 70 degrees with the same pitch. I see no reason to do

"hot pressing" and risk mushrooming the lap tiles --or thermally imprinting

the mirror. (Those who make monolithic, poured and pressed laps must, of

course, do it hot --so hot as to almost be liquid.)

* I ended up making 7 laps for this one 6 inch mirror.

In the future, I'll only need to make the polishing lap once, plus maybe

a dedicated 12 micron grit lap.

* What really works well for adhering the pitch tiles

onto your ceramic (floor tile) grinding tool is to first wipe an almost

dry sheen of turpentine (the real stuff, not "mineral spirits") onto the

ceramic face.

~ Problem: wiping turps will erase

your lap lay-out lines, so deftly wipe/blot within the marked one inch

squares.)

~ I see no need to warm the tool

if the tiles are well candled. (Hold the squares by their opposite corners

--thumb and forefinger. Bring the rough side in close and somewhat under

the base of the candle flame, lest you be burning your fingers. Melt the

pitch just short of it running, then gently wring it down in place.)

~ For the 5th (a full sized) lap,

I tried to stick the pitch tiles onto residual pitch from the recently

removed 4th lap. That was a no-go. Every one of those tiles easily popped

off when tested.

~ It might be that turpentine only

works well for the pine tar based pitch that Willmann-Bell sells.

Pressing:

* I ended up pressing (using 10 pounds total weight,

including the weight of my 6" mirror --or about 6oz/square inch) with a

disk of synthetic window screen against the lap, and a single sheet disc

of (Reynolds brand) non-stick baker's parchment paper between the mirror

and the screen (to keep pitch from sticking to the glass). As the pitch

tiles comes into conformance with the mirror, that screen gave their shiny

surfaces a cerium oxide holding micro-faceted finish, so it's easy to tell

when pressing is sufficiently complete. (Baker's parchment also covers

the floor of my pitch strip mold.)

~ I think it's important to follow

screen pressing with 15 minutes (using 166m test pitch) of pressing with

just parchment (or tracing) paper, since the upwelling of the pitch flow

into the screen is surely irregular.

~ I do not like "direct" cold pressing,

using only cerium oxide or rouge slurry between. Such long contact has

transferred pitch deposits onto the mirror, which then become polish and

test fouling smears.

~ Again: I don't feel that initial

"hot pressing" is necessary for a traditional, discrete tiled lap. Extended

cold pressing works well for me (with 166m test pitch). One might raise

the polishing room temperature 5 degrees.

* Eventually, I ended up using a nominally full size

lap, but with a diminishing bevel --as is the normal practice.

* Mel Bartels

(no slouch!) holds the opinion that an over-sized lap prevents a TDE. (Truth

be known, Mel makes lots of great big mirrors, while I struggled mightily

with my one little piss-ass mirror.)

** The common wisdom is to ensure that the central

tile/square is well off center, so as to not polish in a pattern of zonal

departures, ripples or whatever into the mirror. So far I've been following

that advice, even though I suspect it's hogwash. What's more: I once managed

to "dog-biscuit" my mirror (meaning: mottling/choppiness) --anyway.

Mirror Testing

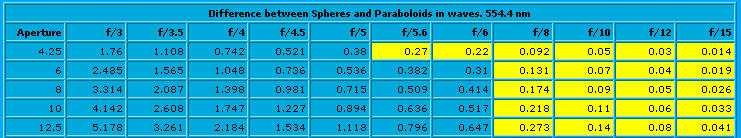

Although our optics goods suppliers, books and Web

resources bespeak surface departure errors in terms of a wave length of

light --implying that our criteria has to do with the heights of a mirror

profile (assuming that the mirror resting on its back), although

venerable authorities would have us graph out those profiles using the

very sensitive Foucault test, those heights are simply a convenient way

to reference mirror quality. It's actually the slopes which produce those

profile heights --it's the average slopes that we see in our tests --and

which confound our efforts to confine a star's image to a point at prime

focus.

These departures, seen at the radius of curvature,

are (of course) from what would be a spherical surface. When we do test

a spherical mirror, it looks perfect: no shadows in the Foucault test,

straight bars in the Ronchi test --which is often called a "null". What

we seek when "figuring" a well polished spherical mirror, however, is a

paraboloidal surface. Interpreting its departure from sphere in an easy

but precision way --is the essence of what follows.

The Ronchi Test

* Some parties in our ATM circles (most notably: Willmann-Bell)

count both the black lines of a Ronchi grating and the equal width

spaces between --such that a grating with 50 black lines per inch is said

to be a "100 line" grating. However, the vast majority of the optical and

science industry outside of our ATM community either counts only the black

lines --or: refers to the (black and white) "line pair" count of a grating

or a resolution target. Seldom do vendors, ATM web pages and other published

articles state which definition is being used.

* Most ATM workers who report and image or illustrate

Ronchi grating results place the grating just inside the focus. Fortunately,

most everyone is keen on stating whether a given Ronchi image or drawing

was inside or outside --because the results are opposite each other. However

--

Jerry Oltion

pointed out to me that a grating placed outside of focus gives a better

indication of the shape of the peripheral zone of a mirror, and he's right.

Once I tried outside-the-focus with a good Willmann-Bell grating, I converted

over from having been an "inside man".

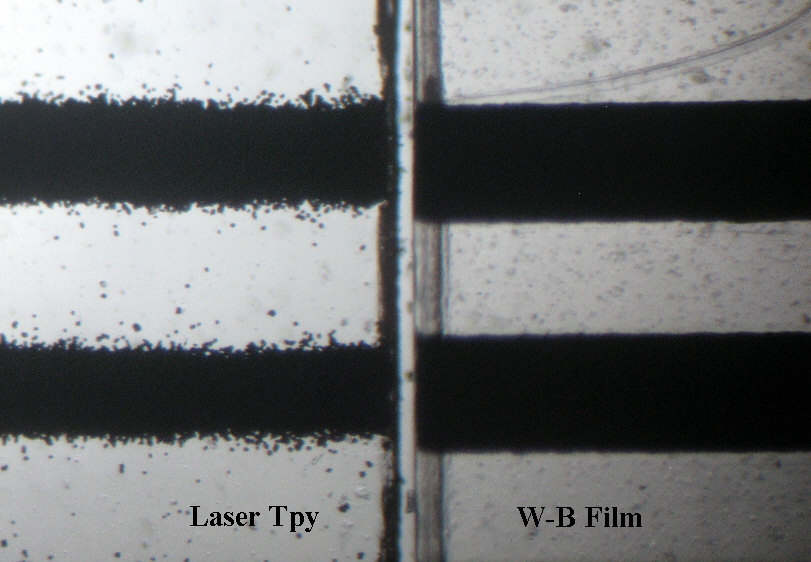

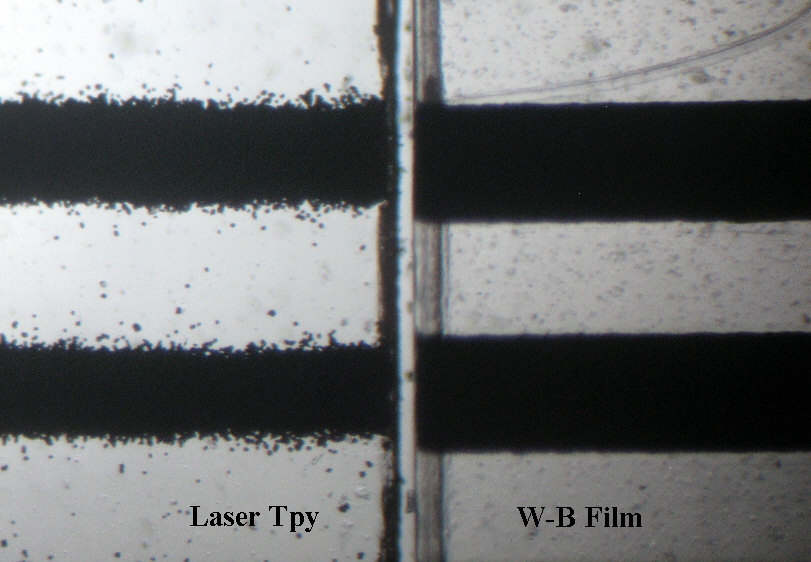

* I can't think of an explanation as to why, but the

Ronchi image is also much sharper outside the focus, and that's with the

(W-B) grating turned to face either way. This phenomenon is much less apparent

when using a laser printed Ronchi grating. Presumably, that's because a

laser printed transparency grating is so crummy:

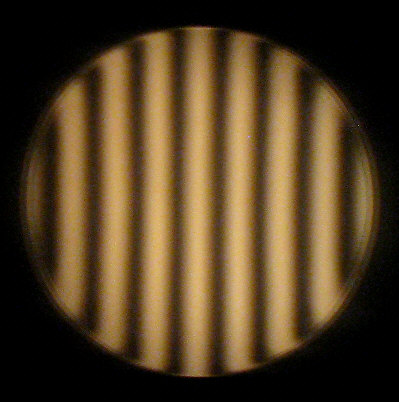

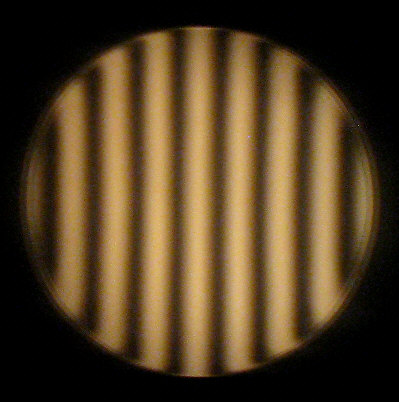

A comparison of two 50 line-pair per inch Ronchi gratings

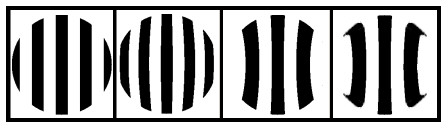

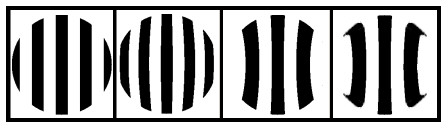

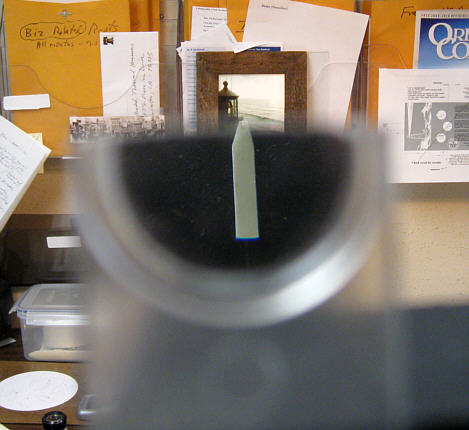

The basic Ronchi images: A - B -

C - D

At left is what we see if the mirror has a nice spherical

surface, for which a Ronchi setup can be considered a fairly good "null

test". The following three Ronchi illustrations (all just outside of focus)

describe other surface shapes, which require seasoned, subjective judgment

to interpret: B: "oblate", meaning flatter (more shallow) than spherical;

C: deeper than spherical (might be paraboloid, might be "hyperboloid",

or too deep); D: deeper than spherical and the edge/periphery of

the mirror either remains sphere --or worse/flatter: the "turned down edge".

* A subtle variation on the above might be a central

area that's sphere, plus an outer/peripheral area that's either paraboloidal,

a different sphere, or oblate/TDE. In either case I go carefully (15 minutes

per session, minimum pressure, using rouge) with a long and wide (4/5ths)

"W stroke". This tends to over-run a TDE, but it also deepens the center^.

Should the center go too deep ("over-corrected"), I

resort to a 1/6th to 1/4th W stroke with medium pressure. That raises the

center --with less tendency toward a TDE than a 1/3rd W smoothing stroke,

but it also tends to make the surface choppy ("dog biscuit") --though not

as badly as does the short "I-stroke".

^ If you're making a small, long focus mirror (say:

f/9), you might be going for a spherical surface, or "figure", which brings

you within 1/8 wave when working a 6 inch mirror. (Presumably, shadowing

by the secondary lessens the effective error of a spherical mirror, but

not significantly for long focus scopes with minimal secondaries.)

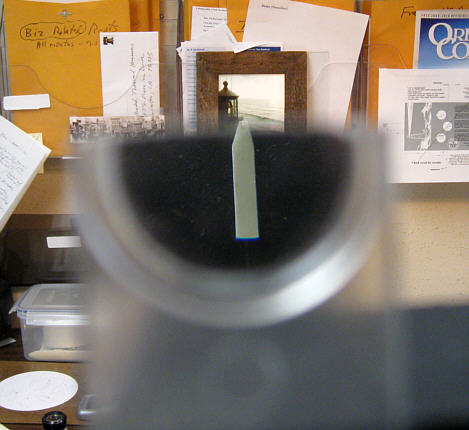

More About Ronchi Testing

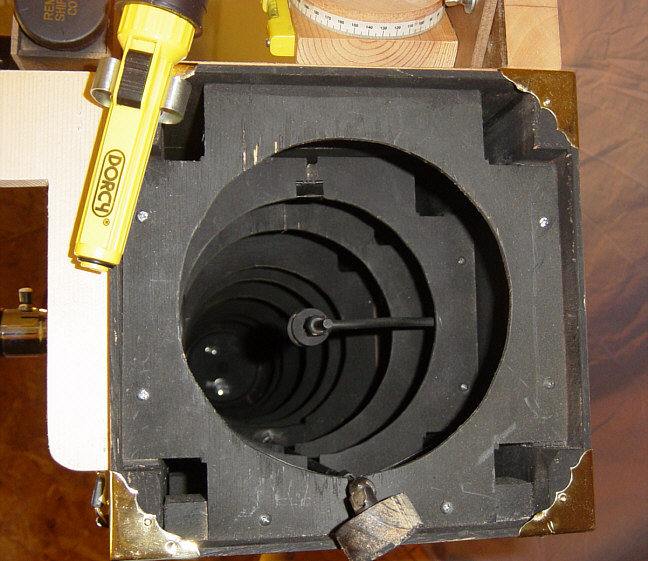

** Being such a lazy barsted, I've found that a (good)

Ronchi grating can be used like a Foucault knife edge (as others have noticed).

I've also skated out on having to add a micrometer pusher or a manipulator

to delicately move the grating left and right. I do lots of nudging, although

it's possible to move the Ronchi bars and adjust the focus point without

touching the Ronchi apparatus --by introducing and twisting glass slides.

(click to enlarge)

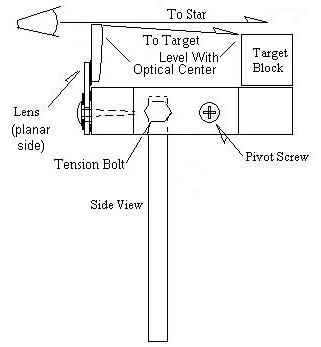

This Ronchi apparatus simply slides along the edge

of a typical long folding table.

Illumination is from an AAA battery pen light shining

through a piece of vellum, and

then a good Willmann-Bell "100 line" (counts 50 line

pairs, actually) grating.

I'm holding a pair of microscope slides (home made,

chamfered edge, 1" x 3.5" window glass). The slides don't have to be optically

flat. (Any introduced problem would be readily apparent, of course).

By placing slides into the beams, the focus point of

the RC (radius of curvature) is lengthened. By checking a stack of slides,

I found that a single piece of 0.110 inch thick, "single strength" window

glass placed in both beams lengthens the focus by 0.035 inch, and by 0.0175

inch in just the return beam. A real (0.050" thick) microscope slide should

lengthen the focus by 0.016", a 0.025" thick cover slip by 0.008". (I've

since made a little slide-around wooden caddy for holding my glass slides

upright.)

If the mirror is on the paraboloidal^ side (its center

having a shorter radius of curvature focus), then use (say) 2 or 3 slides

for a long focus mirror and nudge the Ronchi apparatus to evenly darken

an outer donut area of the mirror first. Next, find out how many slides

to remove in order to darken the center of the donut --and to stop the

apparent Ronchi bars there from moving in the opposite direction when you

budge the apparatus (always moving in from outside the focus).

* I've repeatedly tried using "Couder"^ type masks

and variations on the simpler center-and-periphery masks we see in the

ATM-1 book^, but I feel much more aware of what's going on without masks.

As ATM-1 counsels, we're simply looking at the over-all difference in radius

of curvature, center to edge. That, together with seeing and knowing that

the surface smoothly transits from center to edge --is enough information

for completion.

(^See section II-31 of Texereau's book: "How To Make

A Telescope", pages 94-98 and 220 of ATM-1.)

When such measurements are made by way of using masks

and a Foucault knife edge on (say) a 6 inch mirror, the outer 1/2 inch

is looked at, and maybe a central diameter of 1.5 inches. The simple formula:

difference = r2/RC, gives us a good idea of where we're at,

mirror figure-wise. However: that formula applies to the focus difference

from the dead center to the very edge, versus the actual mean radius we're

looking at somewhat inward from the edge, and somewhat outward from the

center --since we need a goodly area for judging the shadows. Consequently,

"r" might be better taken as 2.5 inches, rather than 3, especially if the

outer edge has a strong bevel, or some TDE is to be abandoned. That would

yield 6.25/102" = 0.061".

~ The inner (say) 1.5 inches of

mirror (ie: a 3/4" radius) only accounts for .563/102 = 0.0055" of the

would-be difference, whereas the jump from r = 2.5 to r = 3 extends the

RC from 0.061" to 0.088" --something worth paying attention to.

~ Using my old eyes (and mind),

and not using a mask, it takes me a while to get grounded as to what I'm

looking and nudging at. I'm watching no less than a central 2 inches of

blob-like diameter (there goes 0.010") and maybe as little as 2.25 inches

of radius for the average "donut" diameter --for a perceived difference

of (maybe) only 0.039". For my (nominally) 6" x f/8.4 mirror (which would

probably work okay even if left spherical), I decided that just one glass

slide's worth of parabolizing difference was going to be just fine.

^ If your mirror is on the "oblate spheroid" side,

you don't need to know by how much. Just fix it.

* In order to tweak a single Ronchi line across your

mirror --or just the inner or the outer zone of your mirror, that can be

done by twisting the slides in the beam a little. However, I find it easier

to just nudge the apparatus or table a little. Sometimes shifting my weight

on the floor will do the adjustment.

* I mark a big fat arrow on the back of my mirror so

that it's always oriented the same for tests. Again: I always come into

the RC focus from outside the focus. The bars are cleaner and I'm better

oriented that way.

~ Be sure to turn off any heaters

in the room, lower the lights, banish your enthusiastic dog and your clumpity-clomp

restless spouse to a distant room, because your home is now made of quivering

Jell-O.

~ Famously: you can fairly determine whether

your mirror is sphere: the Ronchi lines are straight across.

~ When it's deeper than sphere (possibly

a paraboloid): the lines curve to cup away from the center of the mirror

(when seen outside of the RC focus).

~ But: when the Ronchi lines curve a little

to cup the center of the mirror, it's --

slightly oblate

--but at least there's no sign of a TDE here

Not only is this mirror "over-corrected",

but it's got bad TDE as well.

(All of my Ronchigrams are outside of focus)

Is the mirror sufficiently polished

out?

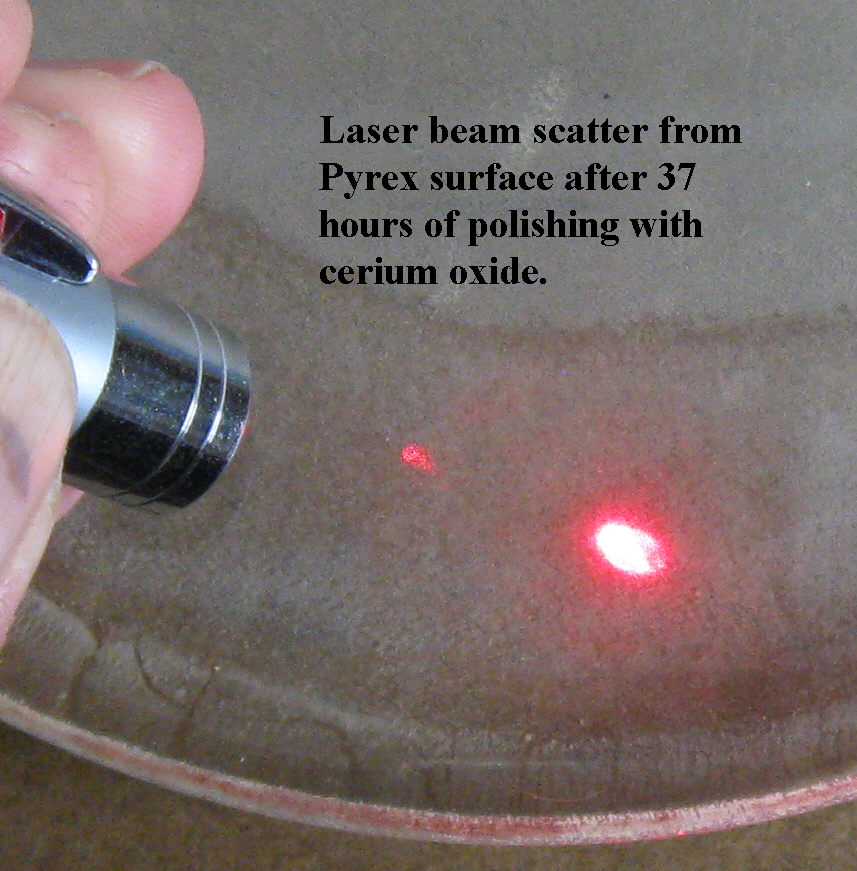

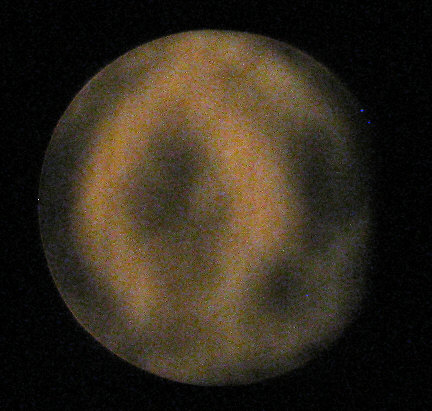

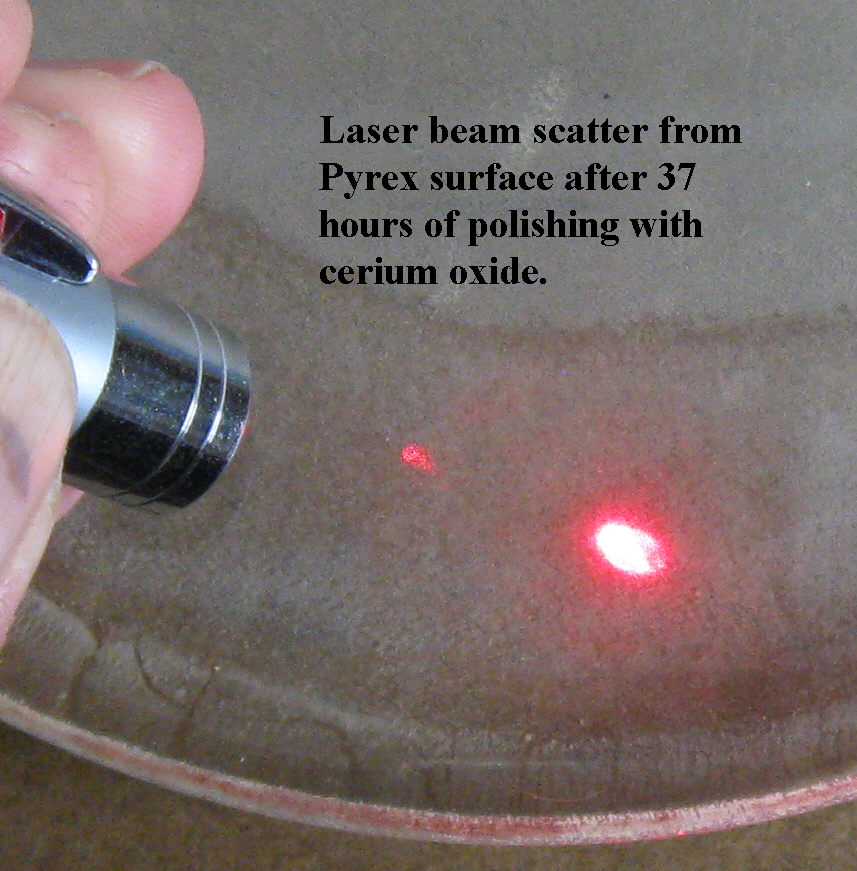

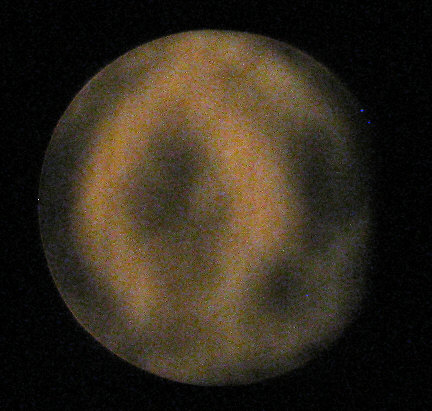

The Laser Test:

* Although any pits were long gone under microscopic

examination, I kept seeing the same, soft, granular light scatter when

giving the surface a laser light test --through 10 hours of polishing.

I switched to using rouge for the final hours of polishing and figuring,

but that made no difference. Perhaps this is just the nature of Pyrex.

A big tip from Jerry

Oltion is to illuminate the surface from just under the mirror's edge

--which eliminates lighting up surface dust --and which might more selectively

illuminate any actual pits. (I've not tried this yet.)

It looked the same at 76 hours, so maybe Pyrex always

shows some sort of surface "grain"?

The brighter spot and that scabby looking stuff is

due to the casting impression on the back (far)

side of the mirror. Next time I'll first grind and

flash polish the back, since it's nice to have a clear

view of the grinding and polishing action (MOT). (Click

to enlarge.)

* At 40 hours, I was still fending off the TDE and

trying to coax a paraboloid out of the recurring sphere. What finally answered

was the classical parabolizing stroke.

The Jerry Test:

Jerry Oltion

recently discovered an excellent way to inspect for pits --which I look

forward to trying. Having previously smoothed and visually polished the

back of your mirror (well enough to observe your progress while grinding

and polishing), turn your cleaned mirror over --face down on a black mat

surface. Shine a bright light into the edge of the mirror, close to the

face. This method makes the remaining pits stand out sharply, but not any

dust stuck to the mirror's face.

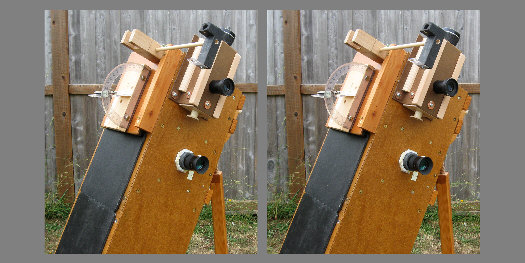

The Star Test

Just as the single "blinking" line Ronchi test, which

is about the same as a Foucault test (which Jerry Oltion calls the "red

blood cell test" --which it resembles) --seems far and away more sensitive

than just looking at Ronchi grating lines, the "star test" is (reportedly)

yet again an order more sensitive. The basic idea is that you need your

telescope in good alignment/collimation and you need to do this test on

a night with good and steady "seeing", such that you can compare a bright

star's highly magnified image to either side of prime focus. Mel Bartels

tells us all about it at:

> www.bbastrodesigns.com/joyofmirrormaking/startesting.html#rigs

--from which page I call your attention to Mel saying:

"--you must learn the star test on small long focus mirrors. This is

the only way to learn the subtleties of the star test. Small long focus

mirrors tend to have fewer confounding defects, are more easily mounted,

tend to be less affected by cooling night air, and [by allowing the

use of less powerful eyepieces] keeps the eye's afflictions out of the

picture. Scopes with 4 to 10 inches aperture and a focal ratio of f/6 to

f/10 are best [to learn with]." With that statement, and with the striking

similarity of Mel's and Jerry Oltion's

star test rigs to a Dogson, I feel comfortable resting my case and advocacies

for

choosing a Dogson scope project.

* However, I find good seeing rather rare where I live

(near the Oregon coast) and the high power star test difficult to interpret.

Polaris seems too dim for my small mirror before it's aluminized, so I

picked out a bright star and manually tracked it. (I'm trying to remember

if I've ever seen a star here that wasn't somehow "boiling".)

* I've several times tried to set up an artificial

star --way up on a great sand dune which peaks about two blocks from our

front yard. However, my solar powered lights up there (clearly visible,

even at dusk) were short lived, thanks to bugs gathering in the dark and

kids gathering by day to tear them up. My impression was that for critical

testing, one must wait until the early morning hours --when the ground

is too cold to be sending up turbulent waves of warmed air. (That might

also be the best time to observe.)

* I tried it one more time with a convex mirror reflector

(that protectively bagged automotive accessory rear view mirror, glued

to the top of my stake, along with a yellow automotive reflector to help

find the stake at night):

--using a 1/8th inch LED aimed off the front of my telescope

--which (I think) the -6 diopter convex mirror effectively reduced to about

0.0007 inch --plenty small, even at only 100 feet. (However: 100 feet is

rather close for null testing a paraboloidal mirror figure.)

--using a 1/8th inch LED aimed off the front of my telescope

--which (I think) the -6 diopter convex mirror effectively reduced to about

0.0007 inch --plenty small, even at only 100 feet. (However: 100 feet is

rather close for null testing a paraboloidal mirror figure.)

I had problems:

~ As mentioned at the top of this

page, the Dogson telescope design is a poor one for low altitude/terrestrial

observation. Although one can hoist the butt end up onto a high stool,

the balance and vibration gets bad. (Adding a purpose built stool would

help solve that problem, but I'm staying with the high astronomical aim

of my Dogson for now.)

~ The thin lens formula has served

me well over the years, but this time I didn't have as much back-focus

(closer subject/longer focus) as I should have. I did managed to squeak

out a 100 foot focus, however.

~ The faint diffraction disk I ended

up seeing was too dim to evaluate, so I'll just forget about testing a

non-aluminized 6 inch mirror this way.

~ The automotive mirror's surface

is simply not good enough. I saw smatterings of more than one point of

light.

~ Some while ago I made an artificial

star source out of a white LED for modeling small obstructed lenses at

50 feet or so --inside the house. Under a microscope its pinhole is quite

round and measures 15 microns (0.006 inch, but to subtend 1/4 arc-sec,

I'd have to place it 400 feet distant --and probably for checkered results

in the early morning hours. ---Hmmnnn

** So: unless someone can think of a much better way

to do it, I vote that star testing, artificial or real, is yet another

"hobby killer" which drains the sap, takes blocks of time away from the

goals of documented celestial observation, creative interpretation and

(at least) personal discovery.

I can see doing a star test at long last with a finished

and aluminized mirror --to document/log the mirror's true condition --should

one ever happen to have a night of great seeing, a high power eyepiece

handy, and a fully collimated 'scope at the same time --but not as yet

another hurdle to clear on your way to the observing chair.

* That leaves me with the fabulous "blinking"

test --aka: the cheap and easy, brighter alternative to Foucault testing,

by using a good Ronchi grating at focus.

* Standard Ronchi testing is,

of course, also very useful.

* The resolution target test:

Click on this image to get a full pixel count version

for your own use.

I printed this target one inch square, laminated it

with shipping tape and made it self-adhesive with double-stick carpet tape

--then stuck it high onto the post of a stop sign --about 330 feet distant

from our front porch. This is a traditional photographic standard for testing/proving

throughput resolution. If my mirrors can separate those bars at an arc-second

or better, what more could I want out of my optics? As it turned out, I

was able to distinguish the line pairs at only 0.81 arc-second --which

worked out to "32" (line pairs per inch) on the target --the diffraction

limit. Although line pairs are easier to see than close binaries or low

contrast planetary details, I can have confidence in this repeatable, "case

closed" test and I'm happy with the result. (Do this test in the early

morning hours, before sidewalks and pavement starts heating up.)

* The "hardware test": There's also the possibility

of using power pole hardware, but I found little by way of bolts with threads

or other repetitive shapes --save for transformer insulators. Those insulators

are too big for "neighborhood" use, but might be great if you have some

distant poles and transformers to examine.

* --And then there's the flattering,

feel-good, "Ronchi eyepiece" test, which is a paraboloidal null test (you

see straight lines). It's not very sensitive, but will reveal gross problems.

It consists of a 35mm film can with a hole in the cap's center --covered

with (say) a small piece of "150 line" (75 line pair) Ronchi grating. If

your mirror is at least a fair paraboloid, you see straight lines when

looking at the light of a star --spread out across your mirror. If that

star is other than Polaris, turn the Ronchi grating to align with the star's

drift to make the lines stand still. Otherwise, let the lines drift across

your image of the mirror and watch to see if they bend and wiggle --meaning

your telescope mirror is a can of worms :-) since this is not a very sensitive

test. (But perhaps it's sensitive enough.)

I'll be trying this test using a piece of positioning

film strip (150 LP/inch) from an old HP printer. and so will another member

of our e-group: Jerry Oltion (Astronomer's Workbench editor for Sky &

Telescope) --who has a much better observing location.

* Update: Jerry did so, carefully checking with 4 telescopes

--the mirrors of which he is very familiar with. Using 150 LP/inch is,

as expected, more sensitive (than half that line count) --perhaps good

enough to prove that a mirror is within 1/4 wave of true, but it's not

as prescriptively sensitive as a proper (in and out of focus), traditional

"star test". My own tests here, under a sky with rotten seeing, exhibited

straight lines across my 6 inch mirror, so two things: The Ronchi eyepiece

test seems to work when the seeing won't support a regular star test --and:

this test (like the others cited on this page) agree that I have a "good

enough" mirror.

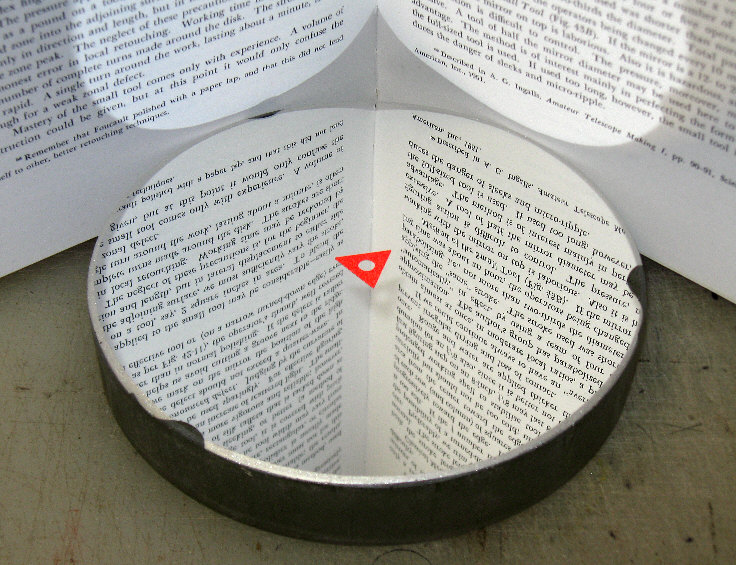

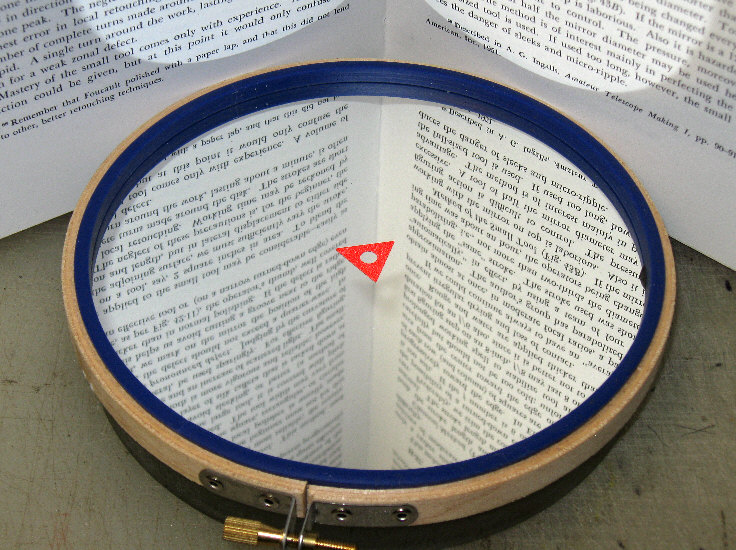

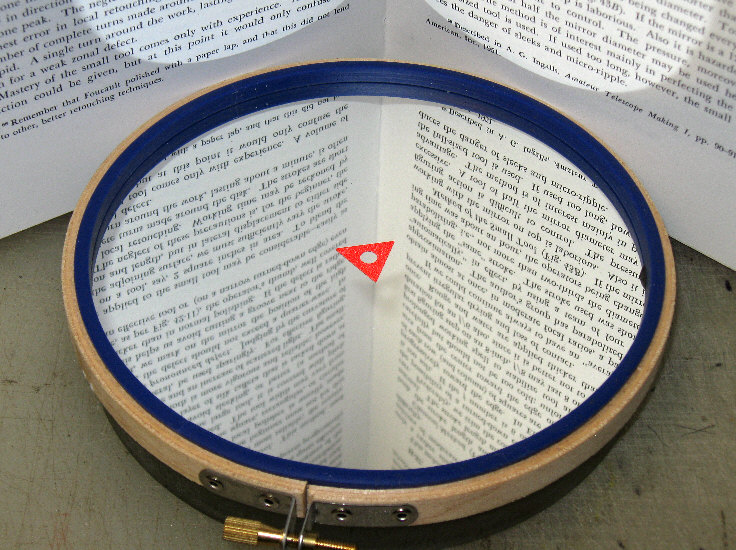

A Grinding and Polishing Cradle

In trying to speed up the process of grinding and polishing,

I became persuaded that the rapid reversal of the mirror's direction (MOT),

when being normally pushed and pulled by gripping the mirror's top edges

--and especially when being moved by means of a traditional "handle", results

in a torque arm (against the inertia of the mirror's mass), which tends

to tip the mirror's leading edge down into the pitch lap --hypothetically

resulting in a TDE. Only after building a "cradle" to

minimize that effect, I found this problem well described on page #344,

and then about the same cradle idea on page #370 of Amateur Telescope Making,

Book #1, but manifested as the "steering wheel dingbat". It was invented

(circa 1930s?) by one J.V. McAdam.

** Although I no longer think that inertial tipping

is much of a factor, a cradle also keeps the heat of my fingers and palms

off the mirror, vastly improves my view of the lap at work, of my stroke

limits and of the periodic rotation of the marked mirror.

* Eventually, I realized that hand heat is very likely

a big factor in pitch hardness for small mirrors, and might well be why

so many 6 inch mirror efforts go south. Obviously, a proportionately larger

(say a) 10 inch mirror has 4.6 times as much mass to heat up, and 2.8 times

the radiation area to shed heat.

Those 3 top Teflon pads applied even downward pressure

on the mirror (or the option of no additional pressure) and the handles

provide alternative positions for old arthritic hands. Unseen is a pad

moderated thumb screw on the far side. Also: the right handle can be turned

to adjust the clearance of the right side bumper pad. The other two pads

are fixed.

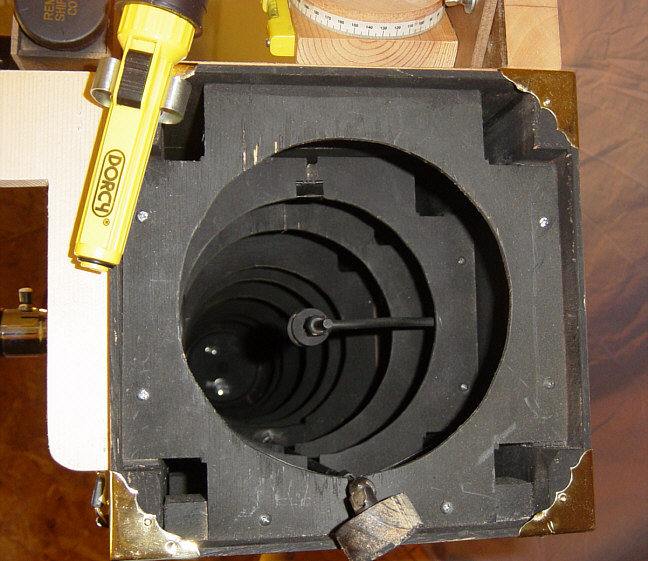

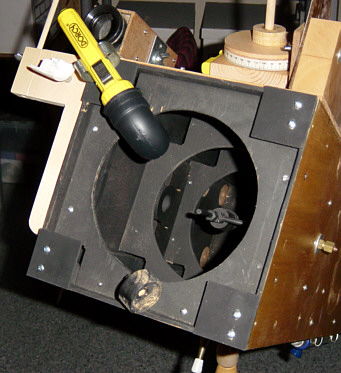

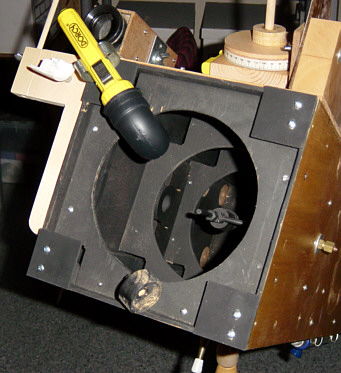

Polishing station (click to enlarge)

Here's a further development---

--in that the widely spaced Teflon pads in the upper view

have been replaced with 4 closely spaced felt pads --in hopes that centrally

concentrated downward pressure (as was the case when straight up stick

handles were used back in the 1930s) --would have less of a tendency to

produce a TDE. (That large, rectangularish patch on the mirror's back is

from the Pyrex blank's casting mold. It seems a good idea to fine grind

and coarsely polish the back of a blank before proceeding.)

Here we see 6 dabs of "office tacky clay" (buy the "Uhu"

brand), which really help to anchor the tool/lap. They work and release

best after getting a tad more dirty than what you see here. Note also my

tool turning index arrow and lap channel alignment lines.

Aside from being spoiled by the cradle's advantages,

I've come to realize how different are my efforts with a polishing cradle,

compared to the hands-on work we read about in our literature and ATM Web

sites. When using such a cradle:

* The mirror is significantly and uniformly colder,

with little or no temperature gradient, mirror back to face. How much the

mirror's temperature gets raised by hands-on polishing is, of course, an

individualized and variable factor that makes advice between workers iffy.

* The lap tiles also run at a significantly lower temperature

(8 degrees lower for me^) --and pitch viscosity is very sensitive to temperature.

^** I borrowed our son-in-law's optical thermometer,

which I first checked out for accuracy and consistency with different materials

(including pitch), finding it to be a good instrument.

^* After 30 minutes of hand "W" (1 inch stroke) polishing

on a 5-1/8" lap --mediated only by surgical gloves for non-slip friction,

I measured (a black tape target on) the mirror back at 82 degrees, (a cerium

oxide slick on) the mirror face at 79 degrees, and the tile faces at 78

degrees. Room temperature was 70.2 degrees.

^* Earlier, after polishing a normal W stroke with

the cradle on a full size lap for 15 minutes, I measured no more than +/-

1 degree differences across the lap face (I was expecting a significant

center to edge difference), and those temps were within 2 degrees of room

temperature. Even with a bit of demon polishing, the difference between

a tile in good contact and one in poor contact was about one degree. (I

had to work quickly to get near instantaneous readings, but I also did

second and third readings after waiting 30 and then 90 seconds for any

deeper tile heat to reach the facet faces.)

* I've read, and it seems intuitive, that there will

always be a bit of TDE --that the simplest cure is to mask it off --maybe

with flat black paint, but I'd use an O-ring.

* My cradle polishing did not go well. Mel suggested

I go to softer pitch and Jerry suggested going to mini or micro facets

--which effectively makes the pitch softer (aside from avoiding possible

stroke length resonance issues). I ended up doing both, but first I changed

just the best candidate: pitch hardness --and in view of the fact that

my polishing lap and mirror temperatures remain near ambient. I made another,

standard, one inch square tiled lap with softer (166 minute plunge test)

pitch --and got much better results.

6 inch mirror project notes section

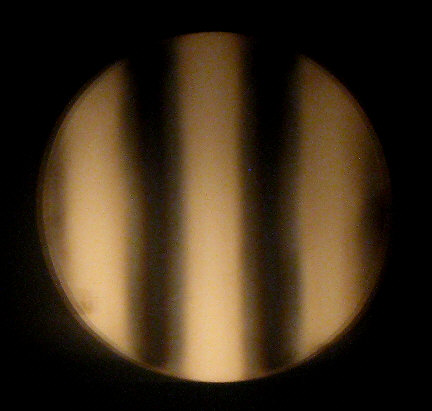

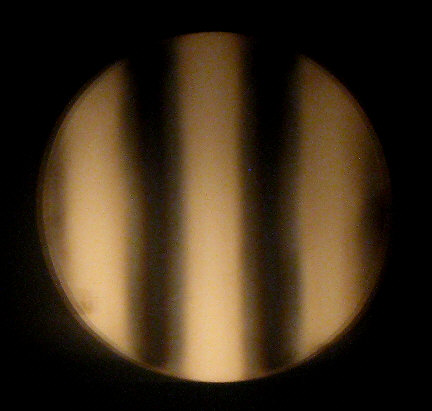

At the 59th Hour (9/15/2015):

Ah do declare: neber did see such a hellatious "hill"

--!-- over half an inch longer in radius of curvature.

The left Ronchigram is at the hill's RC. The middle

image is at the surrounding area's RC.

At right is a general outside Ronchigram. (Wow: looky

dat turned down edge --!)

(Note how one can measure differences in zonal RCs

with Ronchi bars.)

* After seeing that hill, I took notice of a crack

across the central most lap tile. It must have settled lower than the others

(pushed further down by the "bakers parchment paper" I use) --and I failed

to notice the lack of polishing action there. Next I pressed at length

to equalize the tiles --plus I raised the shop temperature to 70+ degrees,

which made my (then) 418 minute test pitch nearly as soft as Gulgolz-64

247 minute pitch.

* ATM mirror work is not yet a science, it refuses

to be so constrained (at least for me), the advice we get is all over the

map --and "the map is not the territory" (Alfred Korzybski).

11/03/2015: Having gone to softer pitch (166 minute

test), I used short (1/6th to 1/4th) "W" stroking to address the TDE. That

"raised" the center, and while it reliably brought a slightly slightly

flatter curve outward from middle to edge with harder pitch (to either

match or to over-run a TDE), the advance of that corrective curve stalled

out with the new 166 minute pitch.

9/24/2015:

9/24/2015:

At 65 hours of polishing (my Ronchis are outside

of focus)

The right image was made by "blinking" with a Willmann-Bell

50 line pair ("100 line") grating.

It was back to using the 1/3rd "W" stroke for smoothing.

Then I had to use an all-out, classical, 4/5 (or so) "parabolizing W stroke"

to get even a hint of producing a parabolic curve. A pleasant and unexpected

benefit of this stroke was that it appeared to keep a TDE at bay.

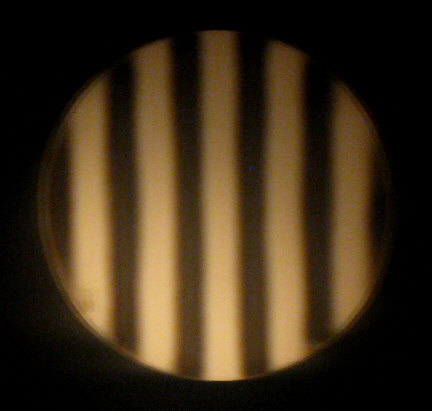

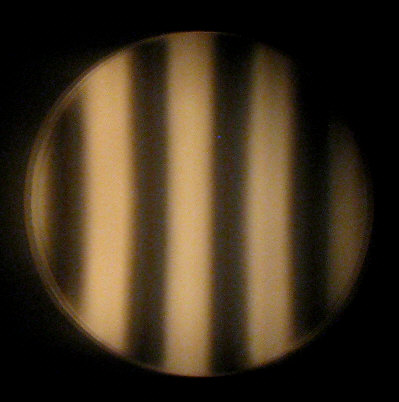

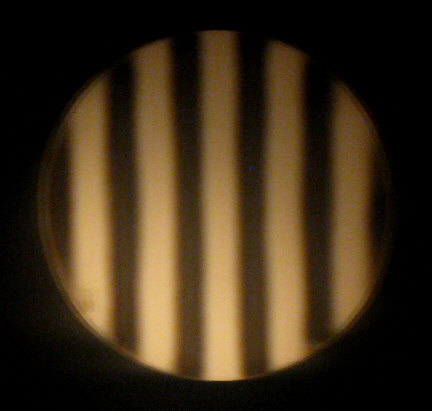

At 72+ hours:

At 72+ hours:

At 72.5 hours of polishing (my Ronchis are outside

of RC focus)

The right image was made by "blinking" the mirror

at focus with a 50 line pair grating.

Here's a dark and grainy actual Foucault-gram (made

with a 30 to 40 micron vertical slit)--

--which confirms that the lumpiness we see in my Ronchi

"blink-o-gram" is real.

My mirror seemed to be getting smoother, but I was

concerned about over-correcting --by continuing with a 4/5th "W" stroke,

1 minute rotations, minimum pressure, and red rouge. -----Hmnnnnn

Again: my polishing was not going well. Mel suggested

I go to softer pitch and Jerry suggested going to mini or micro facets

--which effectively makes the pitch softer (aside from avoiding possible

stroke length resonance issues). I ended up doing both, adjusting the pitch

hardness first. The new, standard, one inch square tiled lap with softer

pitch gave much better results. By impressing micro-facets with window

screen, I got much better "drag".

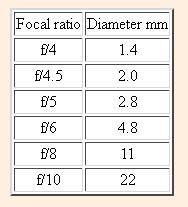

* Here's a cheap and sleazy-easy way

to (needlessly, as it turned out) convert your Ronchi tester to do the

slit Foucault test:

* Here's a cheap and sleazy-easy way

to (needlessly, as it turned out) convert your Ronchi tester to do the

slit Foucault test:

That's a book reading flashlight with a goose-neck.

Simply use a razor knife to cut the slit and the "knife"

edge

against the same straight-edge position (with

smooth plastic

for backing). I got about a 35 micron slit on the

first try.

Work in from outside the focus, so as to nudge the

return image into the knife edge,

rather than trying to chase after it when inside the

RC focus. You can also get numbers.

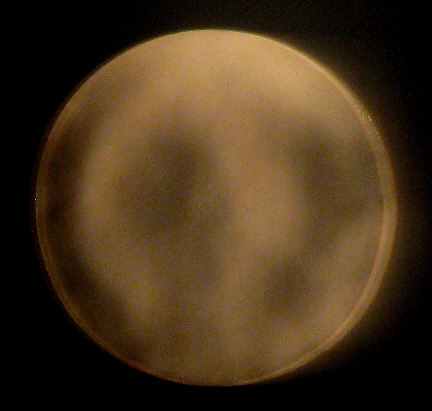

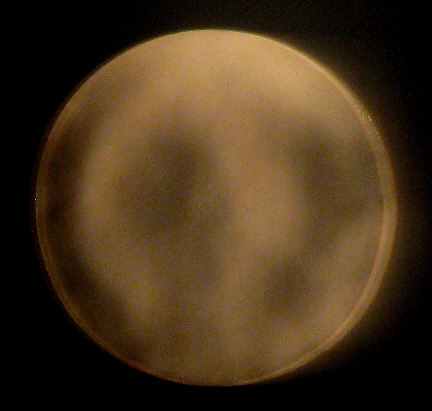

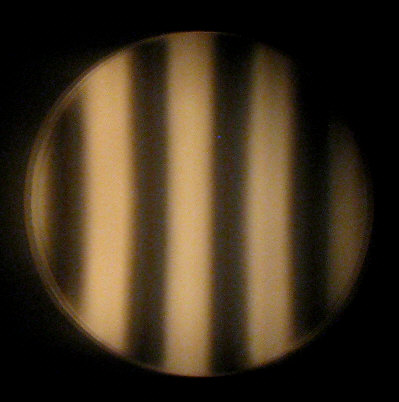

Comments on my 6 inch mirror at 74 hours (images 1,

2, 3, 4)

* Since the Ronchigrams at left are outside of the

RC focus, the mirror, overall, is slightly "oblate".

* My short "W" stroking nearly eliminated the 1/4 inch

or so of "turned down edge" I'd been looking at for days --presumably,

by

adjusting the rest of the mirror to match. Perhaps you can see a vestige

of it by clicking on and enlarging the first image.

* While that slight kink near the ends of the Ronchi

lines might escape casual notice, the reason for it is clearly shown in

the 3rd image, when the Ronchi grating is nudged into position to act like

a bright Foucault test.

* I find this 3rd image difficult to visualize. My

mind's eye wants to imagine a light source to the left. However: once you

"get it" with imagined light from the right, it snaps in and that central

area becomes a "hill" --a big smooth hill, sitting in the middle of a spherical

looking dish.

* It's not an actual hill, of course, but an ever-so-slightly

flatter central area with a slightly longer (radius of curvature) focus.

In the 4th image, the Ronchi apparatus has been gently nudged a wee-bitty

further from the mirror in order to find that longer focus --and Lo: it

"blinked", indicating that it was fairly spherical. (The surrounding area

could be blinked as well, at a slightly shorter focus.)

**At 75.5 hours: At

74 hours I'd proceeded on the gnotion that my (MOT) 1/6th to 1/4th "W"

stroking was slowly marching a flatter spherical curve outward, to over-run

the existing, peripheral spherical curve --taking out any vestigial TDE

in the process.

Nope, it didn't happen. The "hill" area got weaker,

then stronger --but it stayed put. I next used a 1/3rd W stroke --which

once got rid of a choppy surface and produced a nice smooth sphere (but

left some TDE). This time I got a more pronounced hill (again: a central

shallow area, actually).

* My next step was to tear into that stubborn hill

with

a 4/5th W stroke (which always gets results) for a solid half hour, with

medium pressure, rouge, a cradle, and the new 166 minute pitch lap. Although

apprehensive that I'd end up with a badly over-corrected surface, all I

did was remove that pronounced "hill" and produce a perfectly spherical

surface (and just a tad of TDE).

~ Due (surely) to my polishing room

starting out colder than normal --plus my long strokes, a few flakes of

pitch snapped off and smeared up the mirror. It took 3 cleaning sessions

with lighter fluid to get it all off. This has happened before with harder

pitch. I'm glad to report that it doesn't seem to mess up the mirror's

figure.

** At 76 hours:

** At 76 hours:

For the last session, my polishing room started out

cold (66 degrees), so this time I had at it with the 4/5 W stroke again

--but with the room warmed up, and for only 15 minutes per session --with

minimum pressure. The first session produced just a hint of deepening the

mirror's center. The second session's results follow:

Comments on my 6 inch mirror at 76 hours (images 1,

2, 3, 4, 5)

* I roughly measured a center to periphery RC difference

something like 0.035" for this 6" x 50.25" (f/8.38) mirror. I tried measuring

that difference again with masks, but ended up returning to rocking a Ronchi

"blinking" bar back and forth.

* The "star test": We had fair sky with stars (also

with cold, wet and dog poop). I ran the power as high as 196x on a bright

star (Cygnus Alpha/Deneb at mag-1.3), since Polaris seemed too dark for

my unsilvered 6" mirror --but golly: the same(?) mess to either side of

prime focus didn't tell me much.

Hopefully, this "blink tested" tip-of-the-hat to parabolizing

is gud-enuf for a 6" x f/8.4 telescope.

Aluminization: *

My astronomy circle of friends having made no objections to the current

shape of my mirror (what can be seen of it via my Ronchigrams), next up

was to choose a coater and have it aluminized.

Aluminization: *

My astronomy circle of friends having made no objections to the current

shape of my mirror (what can be seen of it via my Ronchigrams), next up

was to choose a coater and have it aluminized.

* The next order of business was to religiously clean

up the mirror. As mentioned above, I ended up having to grind off crusted-on